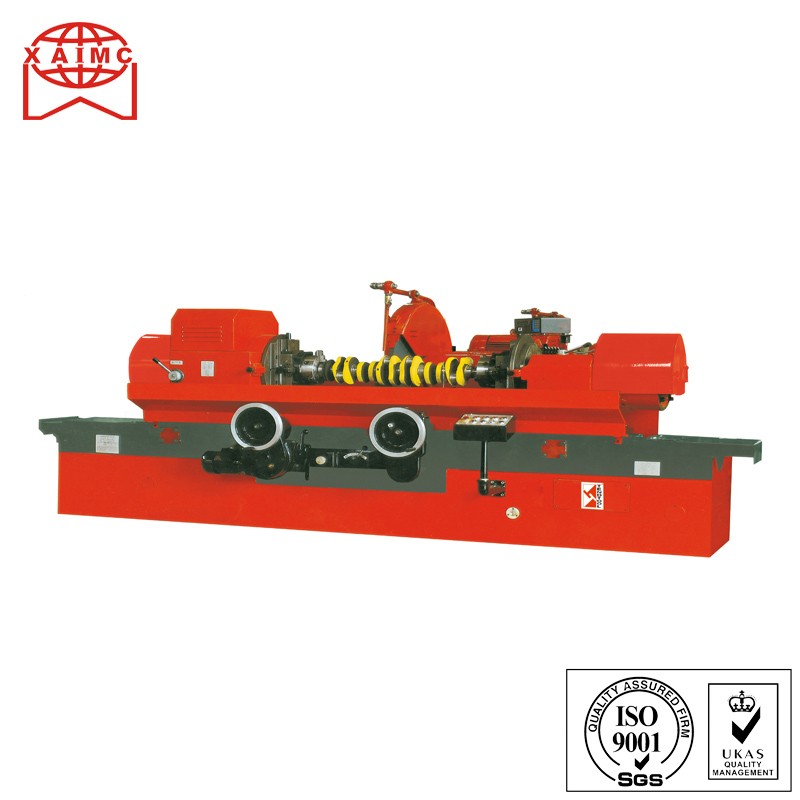

crankshaft grinding machine, crankshaft grinder MQ8260A/C

MQ8260A crankshaft grinding machine is intended for use in automobile, tractor and diesel engine repairing shops to regrind the crankpins and journals of crandshafts. Wheelhead rapid approach and withdrawal is hydraulically effected, the worktable is operated approached either by hand or by power. Power table traverse, either left or right, is momentily actuated by depressing and releasing the electric push button in connection with the desired direction. This arrangement facilitates table spacing for the grinding of the next journal or crankpin.

·Four different work speeds are obtainable by making use of a double – speed motor and the belts in workhead.

·Union chucks are used in the headstock and tailstock for adjusting eccentricity up to 120 mm.

·Friction coupling is used in the headstock transmission chain for its easy adjustment.

·Table longitudinal traverse is operated either by hand or by power.

·Wheelhead rapid approach and withdrawal is effected by hydraulic means .

·Rolling guideways are used on wheelhead and made by high quality material . The wheel spindle being of 80 mm in diameter has good rigidity and strength.

·Plastic coated bed ways with less friction.

·The bed ways and wheelhead ways are lubricated in automatic cycle by means of oil pump.

·The digital display device can be optional.

-

Main specifications

Specifications Model MQ8260A MQ8260A×20 MQ8260C MQ8260C Type Φ580×1600 Φ580×1800 Φ580×2000 Φ600×1600 Φ600×1800 Max.work swing diameter mm Φ580 Φ580 Φ580 Φ600 Φ600 Max.work length mm 1600 1800 2000 1600 1800 Capacity 1.Max.swing over table mm Φ580 Φ580 Φ580 Φ600 Φ600 Work diameter ground with steady rest mm Φ30-Φ100 Φ30-Φ100 Φ50-Φ120 Φ30-Φ100 Φ30-Φ100 Throw of crankshart mm 110 110 120 110 110 2.Max.work length ground:in 3 jaw chuck mm 1400 1600 1800 1400 1800 Between centers mm 1600 1800 2000 1600 1800 3.Max.work weight kg 120 120 150 120 120 Headstock Center height mm 300 300 300 300 300 Work speed r/min 25,45,95 25,45,95 30,45,65,100 25,45,85 25,45,95 Wheel

head1.Max.cross movement mm 185 185 185 185 185 2.Wheel head rapid approach & withdrawal mm 100 100 100 100 100 3.Wheel feed per turn of cross feed handwheel mm 1 1 1 1 1 Per grad of cross feed handwheel mm 0.005 0.005 0.005 0.005 0.005 Grinding

wheel1.Wheel spindle speed r/min 740,890 740,890 740,890 740,890 740,890 2.Wheel peripheral speed m/sec 25.6-35 25.6-35 25.6-35 25.6-35 25.6-35 3.Wheel size(O.Dxwidthxbore) mm Φ900×32(20)×Φ305 Φ900×32(20)×Φ305 Φ900×32(20)×Φ305 Φ900×32(20)×Φ305 Φ900×32(20)×Φ305 Table 1.Table traverse per turn of handwheel Coarse mm 5.88 5.88 5.88 5.88 5.88 Fine mm 1.68 1.68 1.68 1.68 1.68 2.Table swivel(taper 18/100) 5′ 5′ 5′ 3.Table swivelper grad of scale(taper 1:50) 10′ 10′ 10′ Overall capacity of motors kw 9.82 9.82 11.12 9.82 9.82 Overall dimensions(L×W×H) mm 4166×2037×1584 4166×2037×1584 4900×2037×1584 4166×2037×1584 4166×2037×1584 Weight kg 6000 6200 7000 6000 6500 working

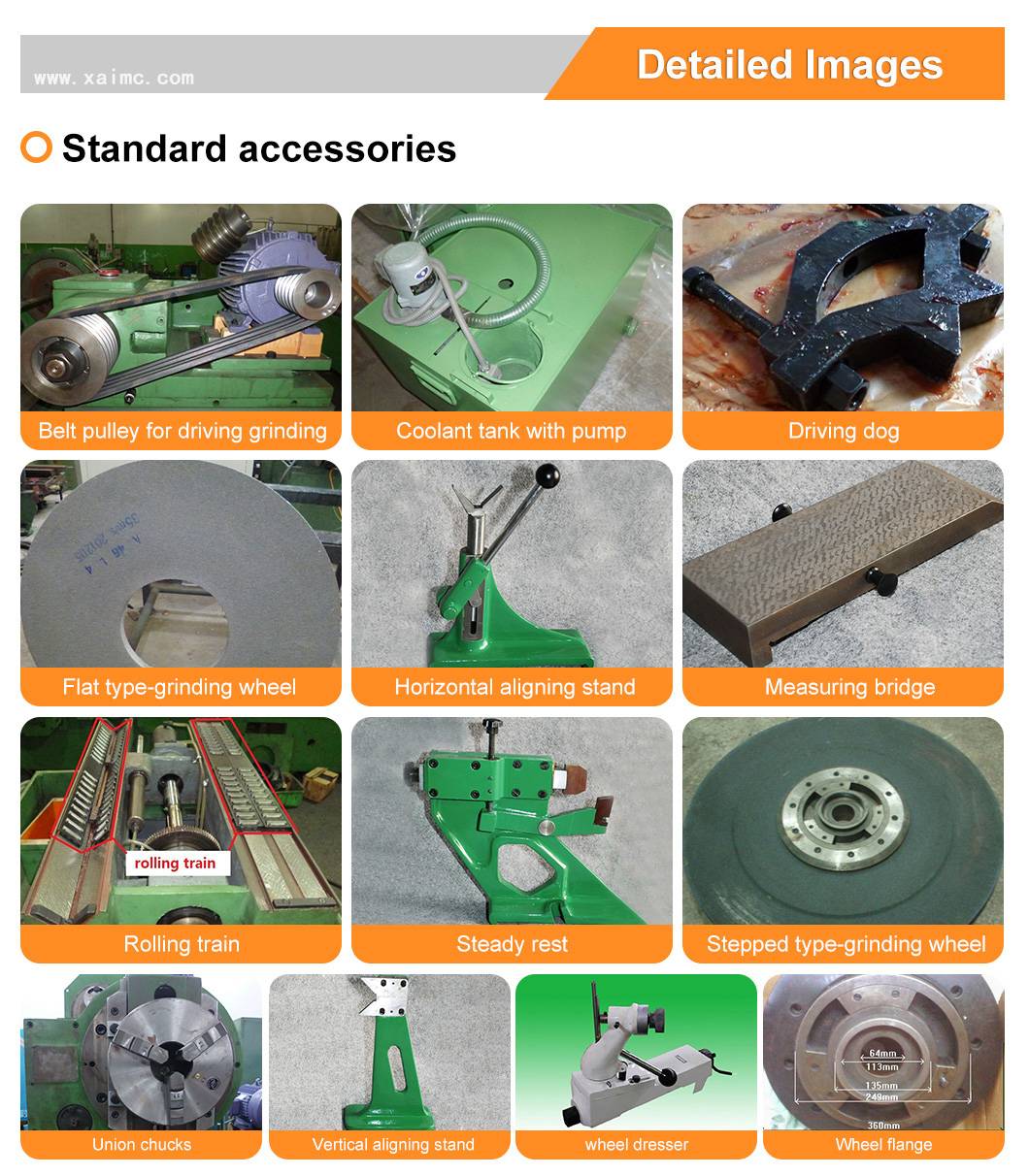

accuracyOvality(new standard) mm 0.005 0.005 0.005 0.005 0.005 Cylindricity mm 0.01 0.01 0.01 0.01 0.01 Roughness Ra um Ra0.32 Ra0.32 Ra0.32 Ra0.32 Ra0.32 - Accessories