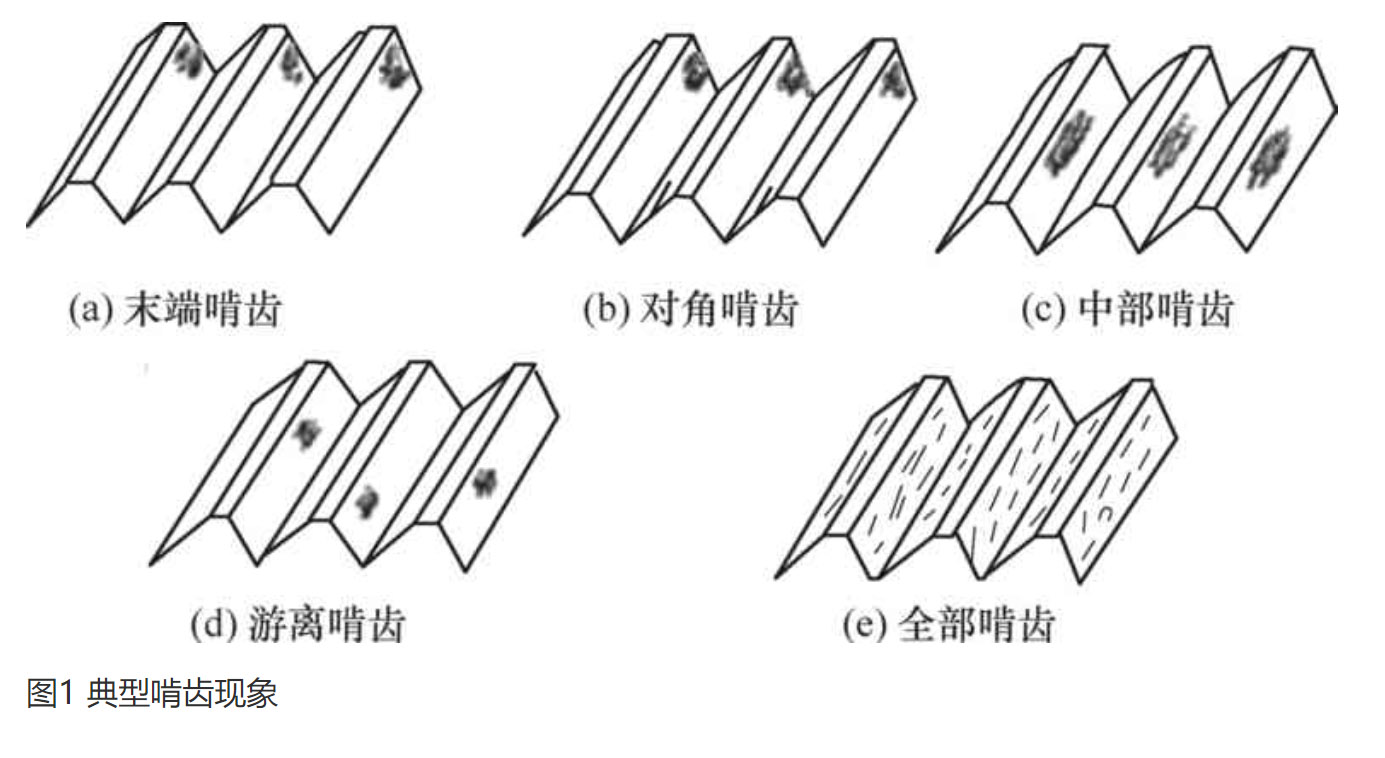

Cutter tooth every time, will form a new tooth surface on the blank cylinder, the tooth is a phenomenon of the tooth surface spot marks and how many different. The concave spot on the tooth surface is caused by the abrupt change of the movement trajectory of the tooth forming. The factors that affect the movement trajectory include the change of cutting load, mechanical wear of transmission system and poor hydraulic and lubrication conditions. In the machining of spur gear, hob spiral direction vertical downward, the installation Angle is very small (generally below 2°), so that the cutting load changes in the whole cutting process is very small, from the tooth to the direction, the main cutting force vertical downward, circular feed component is ignored. Because the tooth direction and the feed direction are parallel, so that the factors in the direction of the speed change will not have an impact on the forming motion track, so in the machining of spur gear, because there is no differential movement, so that the affected factors are reduced, the gnawing phenomenon is relatively light. Typical gnawing phenomena are shown in Figure 1.

When the helical gear is hob, because of the large installation Angle of the hob, the cutting load changes greatly in the cutting process, and the differential movement of the machine tool is increased, the gnawing phenomenon is easy to occur, and the bigger the spiral Angle, the more serious the gnawing.

Figure 1 typical gnawing phenomenon

Second, gnawing cause analysis

- Tooth gnawing is caused by the change of cutting load and excessive transmission clearance

On gear hobbing machine bed during machining, gear hobbing machine bed blade to cut out in the workpiece and cutting, the cutting force will experience size between turns the process of change, which will lead to formed between the gear and the machining of the blade vibration force, this has the characteristics of periodic excitation force, mass production for a long time, makes the fasteners loose, This alternating load is prone to fatigue wear of the transmission parts. Loose and wear make the transmission clearance increase, when subjected to a large change of load, will cause dithering and component movement speed change, and eventually cause the gear forming motion trajectory mutation, the phenomenon of tooth gnawing.

Strengthen cooperation with formal financial institutions. Rural fund mutual-aid societies will pay the deposits they receive from members to financial institutions as guaranties, and obtain funds through loans from financial institutions. Cooperation between financial institutions and mutual funds can not only greatly improve the efficiency of capital use, but also solve the problem of less capital, reduce the cost of credit and avoid credit risks.

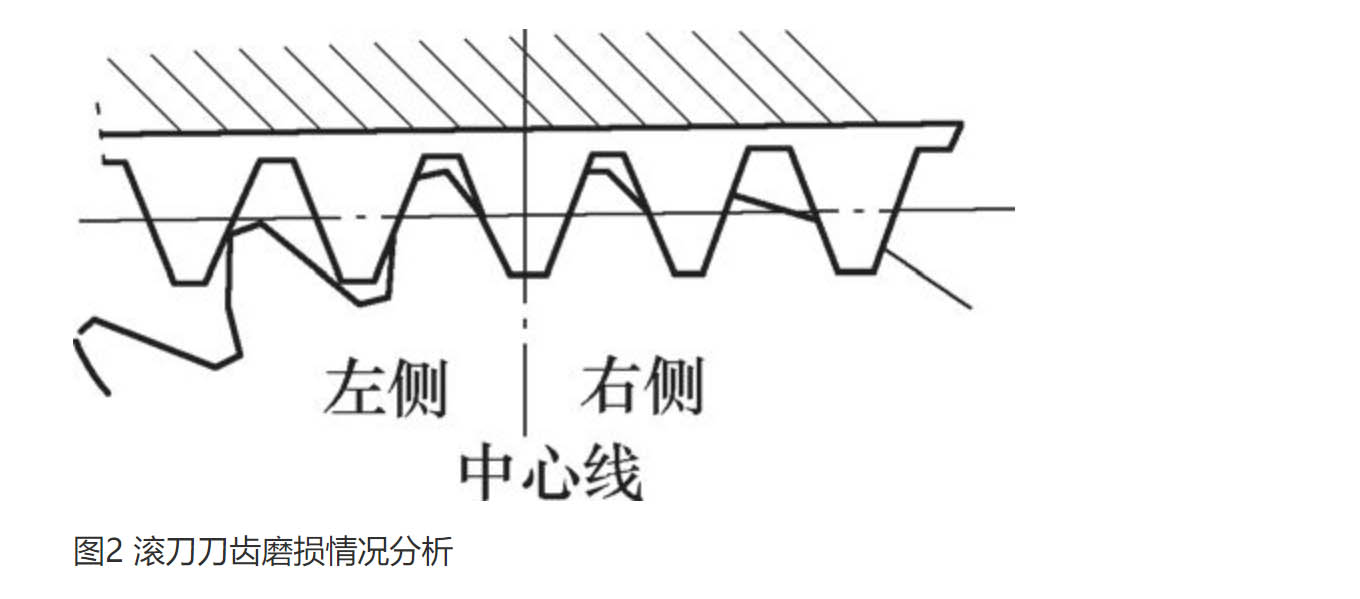

(1) The tool carrier plate is loose and the axial clearance of the tool shaft is too large to cause tooth gnawing. Tool rest is one of the main key parts of the gear hobbing machine. First, analyze the wear of the cutter teeth, as shown in Figure 2, the right tooth cutter of the center line is the cutting cutter, the cutting cutter is the most serious wear, its cutting load is large, and the cutting tooth cutter is mainly for the single tooth shape envelope cutting smooth, small load, but will produce unidirectional extrusion and let the knife.

Figure 2. Analysis of hob tooth wear

In the processing method, there are milling and inverse milling. When machining the left tooth milling, the tool holder from the bottom up feed, cutting tooth cutter is the back of the hob, hob from the top down hob, the cutting reaction force along the hob axis force component R1 and its own quality of the hob spindle component oblique force g1 to eliminate the axial clearance of the tool bar.

Hobbing is one of the most commonly used machining methods with high productivity. Tooth gnawing is very common in gear hobbing processing, if the following process (such as shaving, grinding, etc.) can not correct this error, then the parts can only be scrapped, some gear hobbing is the final process, if there is tooth gnawing, it will lead to a reduction in gear load capacity, transmission instability and noise increase.

In order to reduce hobbing machining defects, ensure gear to meet the use requirements, improve the hobbing fault troubleshooting efficiency, it is necessary to analyze the causes of hobbing defects.

First, gnawing fault phenomenon

Hobbing cutting process, every participating in the cutting of the hob tooth will be cut on the blank cylinder, the cutter tooth every time, will form a new tooth surface on the blank cylinder, the tooth is a phenomenon of the tooth surface spot marks and how many different. The concave spot on the tooth surface is caused by the abrupt change of the movement trajectory of the tooth forming. The factors that affect the movement trajectory include the change of cutting load, mechanical wear of transmission system and poor hydraulic and lubrication conditions. In the machining of spur gear, hob spiral direction vertical downward, the installation Angle is very small (generally below 2°), so that the cutting load changes in the whole cutting process is very small, from the tooth to the direction, the main cutting force vertical downward, circular feed component is ignored. Because the tooth direction and the feed direction are parallel, so that the factors in the direction of the speed change will not have an impact on the forming motion track, so in the machining of spur gear, because there is no differential movement, so that the affected factors are reduced, the gnawing phenomenon is relatively light. Typical gnawing phenomena are shown in Figure 1.

When the helical gear is hob, because of the large installation Angle of the hob, the cutting load changes greatly in the cutting process, and the differential movement of the machine tool is increased, the gnawing phenomenon is easy to occur, and the bigger the spiral Angle, the more serious the gnawing.

Figure 1 typical gnawing phenomenon

Second, gnawing cause analysis

- Tooth gnawing is caused by the change of cutting load and excessive transmission clearance

On gear hobbing machine bed during machining, gear hobbing machine bed blade to cut out in the workpiece and cutting, the cutting force will experience size between turns the process of change, which will lead to formed between the gear and the machining of the blade vibration force, this has the characteristics of periodic excitation force, mass production for a long time, makes the fasteners loose, This alternating load is prone to fatigue wear of the transmission parts. Loose and wear make the transmission clearance increase, when subjected to a large change of load, will cause dithering and component movement speed change, and eventually cause the gear forming motion trajectory mutation, the phenomenon of tooth gnawing.

Strengthen cooperation with formal financial institutions. Rural fund mutual-aid societies will pay the deposits they receive from members to financial institutions as guaranties, and obtain funds through loans from financial institutions. Cooperation between financial institutions and mutual funds can not only greatly improve the efficiency of capital use, but also solve the problem of less capital, reduce the cost of credit and avoid credit risks.

(1) The tool carrier plate is loose and the axial clearance of the tool shaft is too large to cause tooth gnawing. Tool rest is one of the main key parts of the gear hobbing machine. First, analyze the wear of the cutter teeth, as shown in Figure 2, the right tooth cutter of the center line is the cutting cutter, the cutting cutter is the most serious wear, its cutting load is large, and the cutting tooth cutter is mainly for the single tooth shape envelope cutting smooth, small load, but will produce unidirectional extrusion and let the knife.

Figure 2. Analysis of hob tooth wear

In the processing method, there are milling and inverse milling. When machining the left tooth milling, the tool holder from the bottom up feed, cutting tooth cutter is the back of the hob, hob from the top down hob, the cutting reaction force along the hob axis force component R1 and its own quality of the hob spindle component oblique force g1 to eliminate the axial clearance of the tool bar.