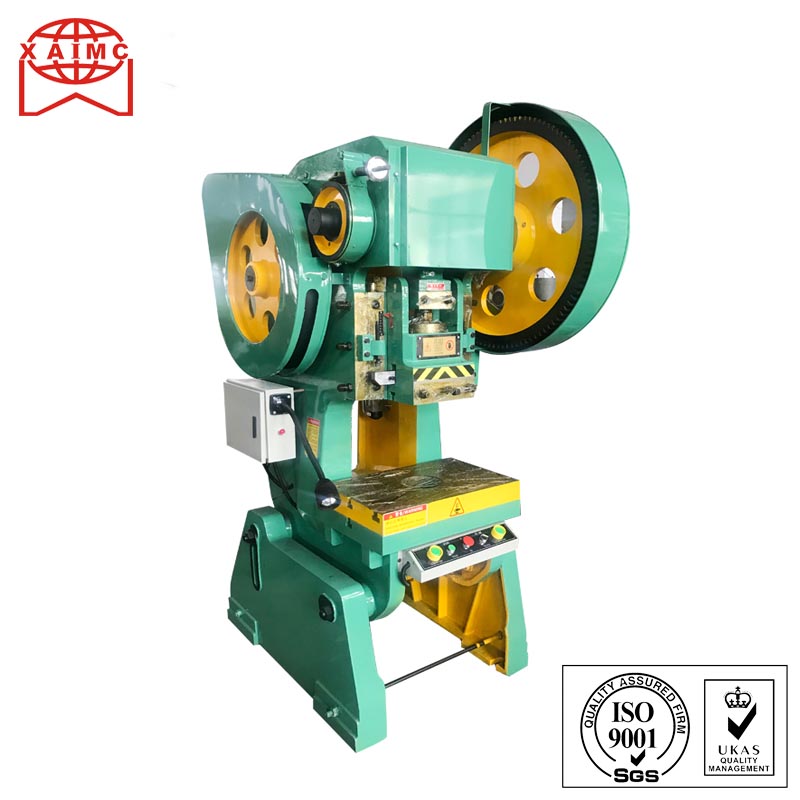

Mark & model : J23 series

Origin : Asia and Pacific Area China

Quality standard : International

H.S.Classification : Machinery & Electronics Machines for Working Metal 8462 Machine tools for forging, hammering, bending, die-stamping etc.

Product profile :

Press Machine Open Back Inclinable Mechanical Press Machine J23 Series

| JC23-6.3 | J23-10B | J23-16 | J23-16B | J23-25A | JG23-35A | ||

| Capacity | kN | 63 | 100 | 160 | 160 | 250 | 350 |

| Nominal Force | mm | 3 | 4 | 5 | 5 | 5 | 5 |

| Slide Stroke | mm | 35 | 60 | 55 | 70 | 80 | 100 |

| SPM | min -1 | 170 | 145 | 125 | 125 | 60 | 53 |

| Max. Die Height | mm | 110 | 130 | 160 | 170 | 180 | 180 |

| Die Height Adjustment | mm | 30 | 35 | 45 | 45 | 70 | 75 |

| Between Slide Center & Frame | mm | 110 | 130 | 160 | 170 | 210 | 200 |

| Bolster (FB × LR) | mm | 200×310 | 240×360 | 300×450 | 320×480 | 400×600 | 380×610 |

| Bolster Opening (Up Hole Dia. × Dpth × Low Hole Dia.) |

mm | Φ60 | Φ120×20 ×Φ100 |

Φ100 | Φ100 | Φ120 | Φ130 |

| Bolster Thickness | mm | 40 | 50 | 40 | 60 | 70 | 70 |

| Bolster Opening (Dia. × FB × LR) | mm | Φ140×110×160 | Φ130×90 ×180 |

Φ210×160 ×240 |

Φ210×160 ×240 |

Φ180×130 ×260 |

Φ180×130 ×290 |

| Slide Area (FB × LR) | mm | 120×140 | 150×170 | 180×200 | 180×200 | 210×250 | 210×250 |

| Shank Hole (Dia. × Dpth) | mm | Φ30×55 | Φ30×55 | Φ40×60 | Φ40×60 | Φ40×70 | Φ40×60 |

| Max. Inclined Angle | ° | 30° | 25° | 25° | 25° | 25° | 25° |

| Between Columns | mm | 150 | 180 | 220 | 220 | 260 | 300 |

| Motor Power | kW | 0.75 | 1.1 | 1.5 | 1.5 | 2.2 | 3 |

| Outline Size (FB × LR × H) | mm | 780×610 ×1505 |

915×700 ×1690 |

1150×900 ×1910 |

1150×900 ×1910 |

1325×990 ×2140 |

1490×1080 ×2200 |

| Net Weight | kg | 360 | 600 | 1080 | 1080 | 1900 | 2440 |

| JG23-40A | JC23-63A | JD23-63A | J23-80A | JD23-80A | ||

| Capacity | kN | 400 | 630 | 630 | 800 | 800 |

| Nominal Force | mm | 6 | 8 | 8 | 9 | 9 |

| Slide Stroke | mm | 120 | 120 | 120 | 130 | 130 |

| SPM | min -1 | 55 | 50 | 50 | 45 | 45 |

| Max. Die Height | mm | 220 | 270 | 270 | 290 | 290 |

| Die Height Adjustment | mm | 80 | 80 | 80 | 100 | 100 |

| Between Slide Center & Frame | mm | 260 | 260 | 260 | 270 | 300 |

| Bolster (FB × LR) | mm | 480×710 | 480×710 | 480×710 | 520×860 | 580×860 |

| Bolster Opening (Up Hole Dia. × Dpth × Low Hole Dia.) |

mm | Φ220×25 ×Φ180 |

Φ220×45 ×Φ180 |

Φ200×45 ×Φ180 |

Φ200×45 ×Φ180 |

Φ200×45 ×Φ180 |

| Bolster Thickness | mm | 80 | 90 | 90 | 100 | 100 |

| Bolster Opening (Dia. × FB × LR) | mm | Φ200×150 ×300 |

Φ250×200 ×340 |

Φ250×200 ×340 |

Φ250×200 ×340 |

Φ280×220 ×380 |

| Slide Area (FB × LR) | mm | 270×320 | 280×320 | 280×320 | 280×380 | 280×380 |

| Shank Hole (Dia. × Dpth) | mm | Φ50×70 | Φ50×80 | Φ50×80 | Φ60×75 | Φ60×75 |

| Max. Inclined Angle | ° | 25° | 25° | 25° | 20° | 20° |

| Between Columns | mm | 300 | 350 | 350 | 410 | 410 |

| Motor Power | kW | 4 | 5.5 | 5.5 | 7.5 | 7.5 |

| Outline Size (FB × LR × H) | mm | 1600×1180 ×2310 |

1810×1350 ×2640 |

1885×1350 ×2670 |

1810×1410 ×2790 |

1990×1410 ×2945 |

| Net Weight | kg | 3180 | 4000 | 4970 | 4790 | 5970 |

Electrical box

motor

Machine regulating screw

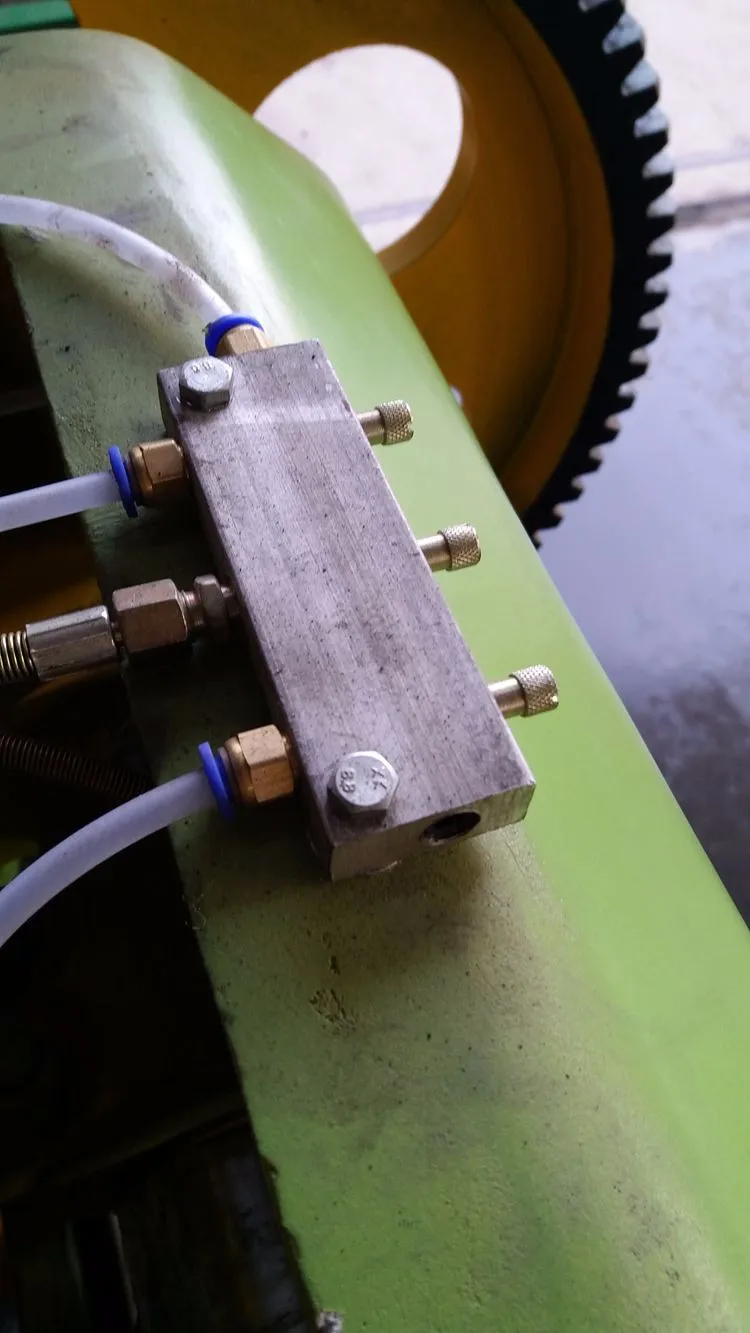

Lubrication device