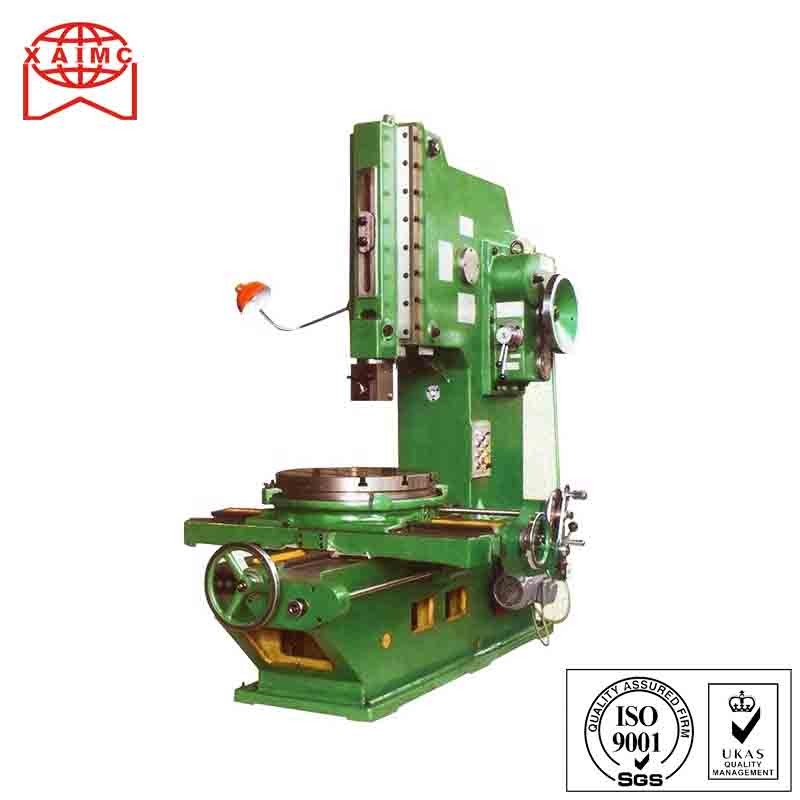

Heavy Duty Metal Slotting Machine B5020 / B5032 / B5040 / B5050

Product Description

Application:

1.The working table of the machine tool is provided with three different directions of feed (longitudinal, horizontal and rotary), therefore work object go through once clamping, Several surfaces in the machine tool machining

2.Hydraulic transmission mechanism with sliding pillow reciprocating motion and hydraulic feed device for working table.

3.The sliding pillow has the same speed in every stroke, and the movement speed of the ram and the working table can be adjusted continuously.

4.Hydraulic control table have ram commutation oil for oil reversing mechanism, In addition to hydraulic and manual feed outer, Even there single motor drive vertical, horizontal and rotary fast moving.

5.Use hydraulic feed the slotting machine, Is when the work is over turning back instantaneous feed, Therefore be better than mechanical slotting machine used drum wheel feed.

1.The working table of the machine tool is provided with three different directions of feed (longitudinal, horizontal and rotary), therefore work object go through once clamping, Several surfaces in the machine tool machining

2.Hydraulic transmission mechanism with sliding pillow reciprocating motion and hydraulic feed device for working table.

3.The sliding pillow has the same speed in every stroke, and the movement speed of the ram and the working table can be adjusted continuously.

4.Hydraulic control table have ram commutation oil for oil reversing mechanism, In addition to hydraulic and manual feed outer, Even there single motor drive vertical, horizontal and rotary fast moving.

5.Use hydraulic feed the slotting machine, Is when the work is over turning back instantaneous feed, Therefore be better than mechanical slotting machine used drum wheel feed.

Product Description

|

Specification

|

Unit

|

B5020

|

B5032

|

B5040

|

B5050

|

|

Max. stroke of RAM

|

mm

|

220

|

340

|

400

|

500

|

|

Maximum ram slotting length

|

mm

|

200

|

320

|

500

|

2000

|

|

Ram motion frequency

|

time/min

|

32.50.80.125

|

20.32.50.80

|

20.32.50.80

|

9,12.5,18,25,36,50

|

|

Ram tilt angle

|

°

|

0-8

|

0-8

|

315

|

430

|

|

Ram vertical adjustment distance

|

mm

|

230

|

315

|

0-8

|

+/-10

|

|

Cutter head bearing surface to the distance between the forearm bed

|

mm

|

485

|

600

|

630

|

1000

|

|

Table Diameter

|

mm

|

500

|

630

|

600

|

990

|

|

The distance between the lower end of the sliding frame to work table

|

mm

|

320

|

490

|

690

|

740

|

|

Max. longitudinal moving distance of working table

|

mm

|

500

|

630

|

620

|

1000

|

|

Max. transverse moving distance of working table

|

mm

|

500

|

560

|

560

|

660

|

|

Table maximum rotation angle

|

°

|

360

|

360

|

360

|

360

|

|

Vertical and horizontal table power feed range

|

mm

|

0.08-1.21

|

0.08-1.21

|

0.08-1.21

|

0.1-1.2

|

|

Motor power

|

kw

|

3

|

4

|

4

|

7.5

|

|

Motor speed

|

r/min

|

1430

|

1430

|

1430

|

1430

|

|

Machine weight

|

kg

|

2200

|

3000

|

3700

|

10300

|

|

All dimension

|

mm

|

191*130*199

|

226*149*224

|

229*152*248

|

340X208X330

|