702 BIG BLOCK CHEVY BOAT ENGINE

Looking to replace a 632 blower engine and get more efficient horsepower in a boat application, Rich Franzman got to work building a normally aspirated 702 cubic inch big block Chevy. See what went into the new build!

Growing up in the ‘60s, Rich Franzman came of age during a time when big engines and auto racing were all the rage. As such, his parents had a job shop where they manufactured valvetrain components for COMP, Isky, Erson, Scat, and others. Rich got the opportunity to cut his teeth on engine mock-ups and machining equipment set ups.

If that didn’t have him hooked on this industry, a 455 Oldsmobile big block in his first car and a Stevens flat bottom boat with a 455 in it as well, surely sealed the deal. Franzman knew engines would be in his life for a long time!

Aside from his parents’ shop, Franzman also worked for Eric Nessa at Precision Machine Industries where he further developed his engine building skills. Today, he owns and operates Rich Franzman Race Engines in Lake Havasu City, AZ. In total, Rich has been building engines for 44 years.

One of his most recent builds is a 702 cubic inch big block Chevy engine to replace a blown 632 in a boat application. Rich says the engine build came about because he was looking for more efficient power as the reciprocating weight of the 632 was doing more harm than good.

“The big blower, compressing air, extra weight, pulleys and other aspects of the blown 632 were killing power,” he says. “When I set out to build this monster, I took advice from Bruce Lee and ‘absorbed what was useful, discarded what was useless and added what was specifically my own.’ I took this as the motto of the engine build. I knew I needed to shed some weight off the reciprocating assembly to maximize power.”

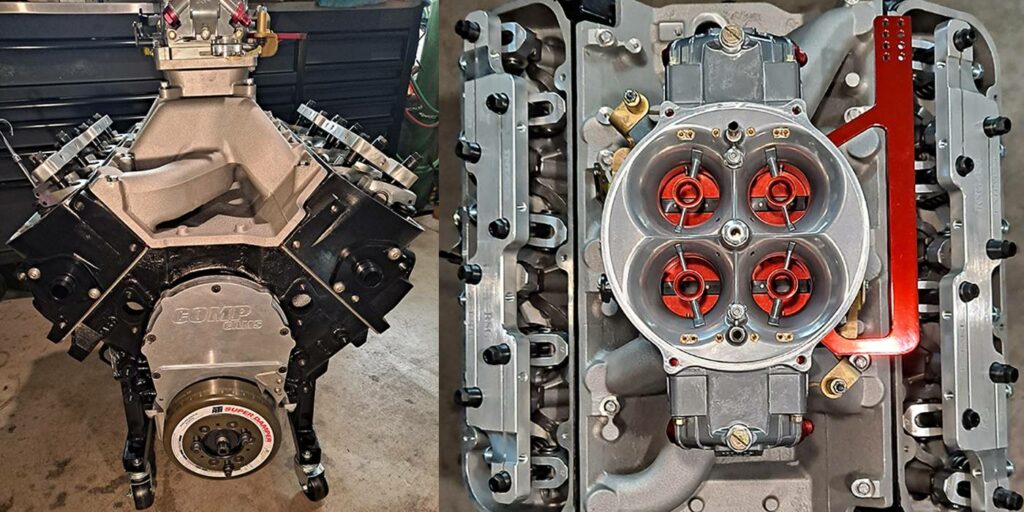

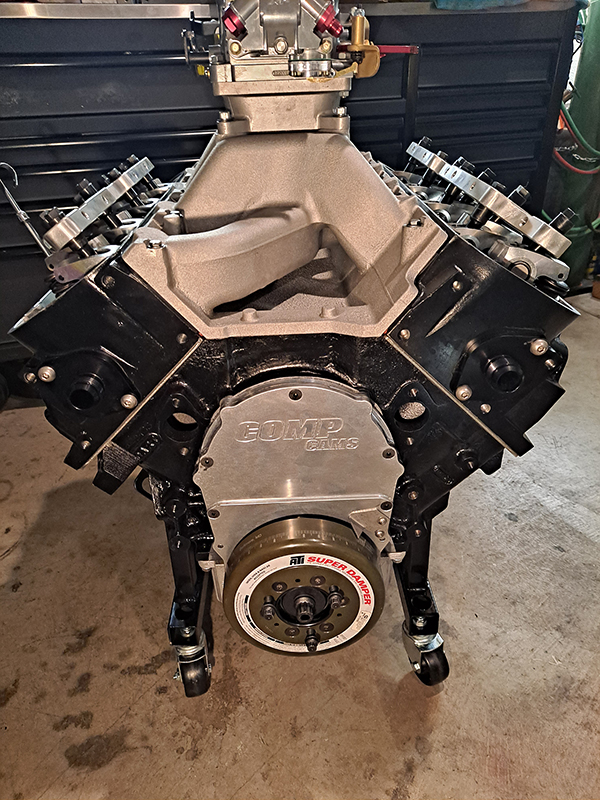

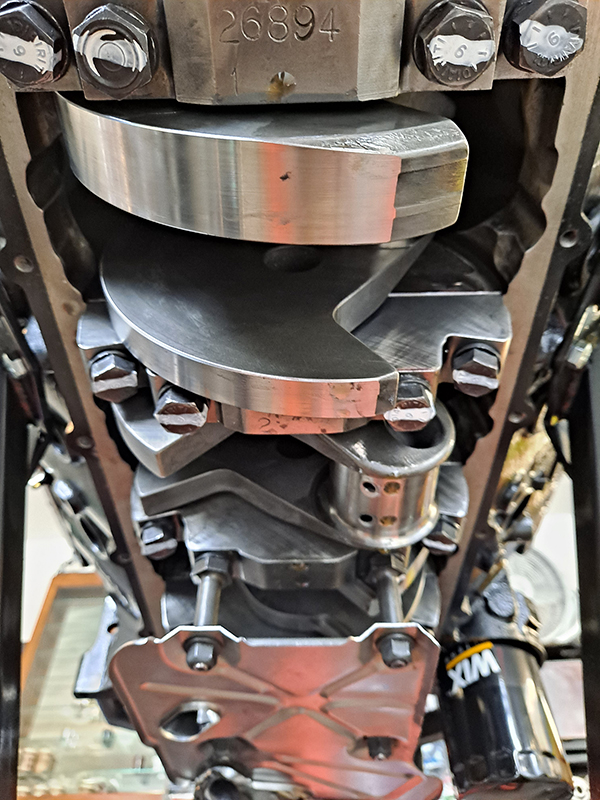

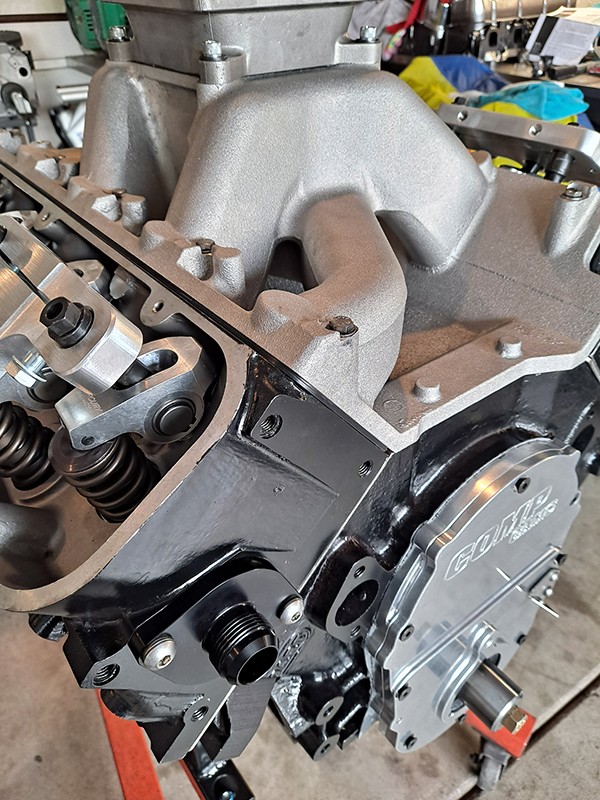

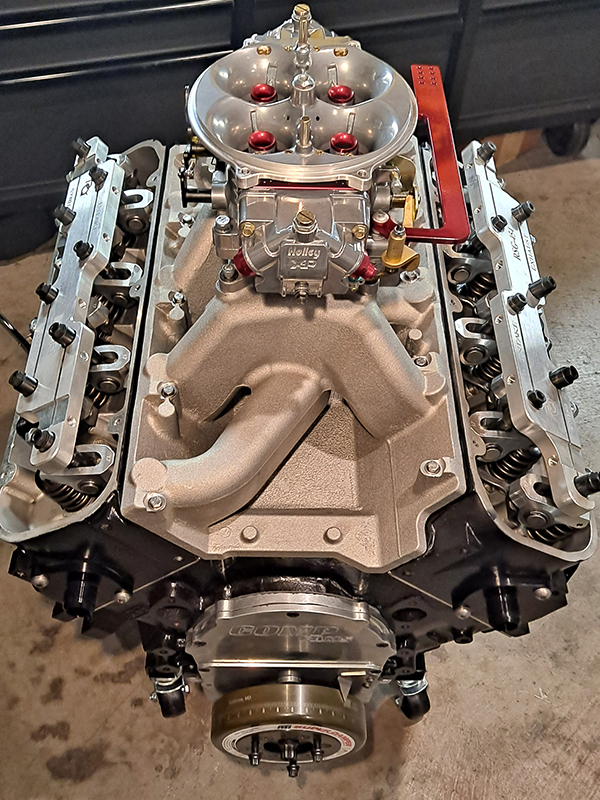

Franzman started the 702 big block Chevy build with a Dart 10.200˝ tall deck iron block, which has the widest pan rails of the castings – a whole .250˝ between the pan rails – for extra real estate when stroking. The rotating assembly of the 702 BBC includes a 5.000˝ stroke 4340 crankshaft, which was cut for counterweights and had “gold” mallory added for balancing. Franzman chose 6.700˝ rods with ARP 2000 rod bolts and JE F.S.R. forged dome pistons with a low-friction .043/.043/3.0mm ring package.

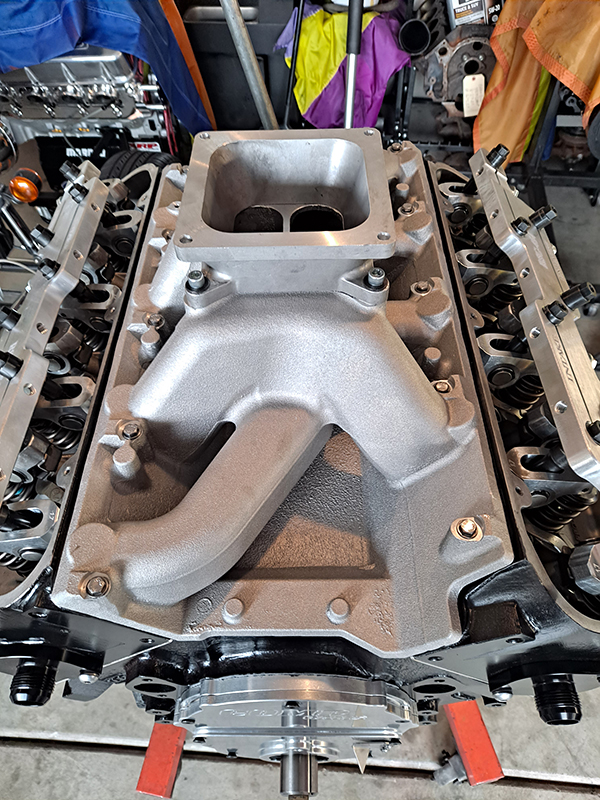

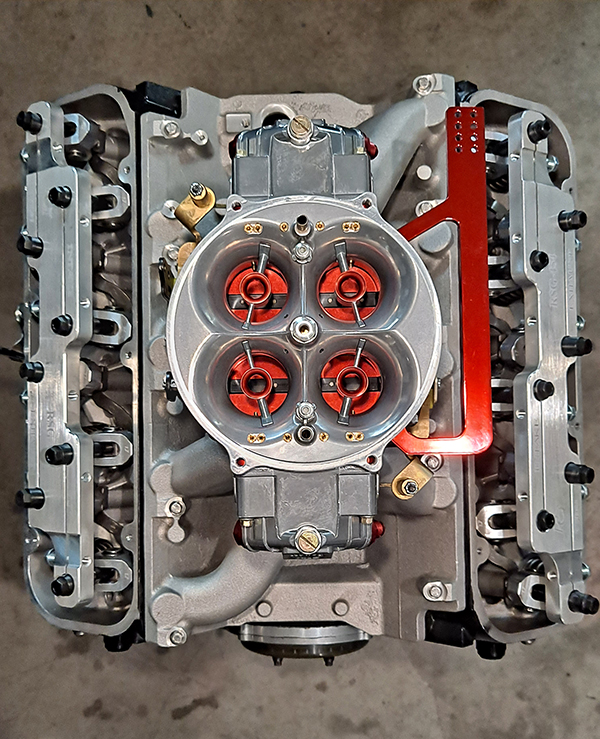

Some of the other components of the build include a Dart sequential cathedral port intake manifold, a COMP Cams timing cover, a Holley 1150 carburetor, Mercury Marine HD trunnion roller rocker arms, a mechanical roller camshaft, and performance-upgraded, aluminum Raylar cylinder heads.

The mechanical roller camshaft features a 310/334 duration and .846/.800 lift with lobe separation of 114. The Raylar heads are lightweight and flow well with the sequential, large cathedral ports, and according to Franzman, the price was affordable.

“The Raylars I set up myself for .825 lift with 14+2 LS 4/7 firing order swap,” he says. “Not many builders realize that Dart’s manifold #41616010 for the single carb and cathedral port design is designed only for that firing order. You cannot use a 4/7 swap and a manifold that’s not designed for the 4/7 concept and expect numbers to gain. Howard’s lightweight, solid lifters with the EDM oil hole that oils the cam lobe will keep the cam lubricated.”

Some of the work on the aluminum Raylar heads include CNC machining and porting, a five-angle valve job, steel valve seats, bronze valve guides, new valve seals, Nitride-treated intake and exhaust valves (2.25˝ intake / 1.88˝ exhaust) with 11/32 stainless steel valve stems, hardened-steel rocker arm studs, 107cc combustion chambers, 315cc high-velocity intake ports, and 135cc high-velocity exhaust ports.

In all, Franzman is looking for 900-1,100 horsepower out of this 702 big block Chevy, and is aiming to stay down low with rpms between 5,700-6,300 at WOT for long periods of time. In order to achieve that, the engine has big water fittings on the sequential and cathedral shape port heads to help scavenge heat.

Now all that’s left for Franzman to do is get the 702 big block Chevy in a boat and go have some fun on Lake Havasu!

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original, Scat Crankshafts and Engine & Performance Warehouse Inc./NPW Companies. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].