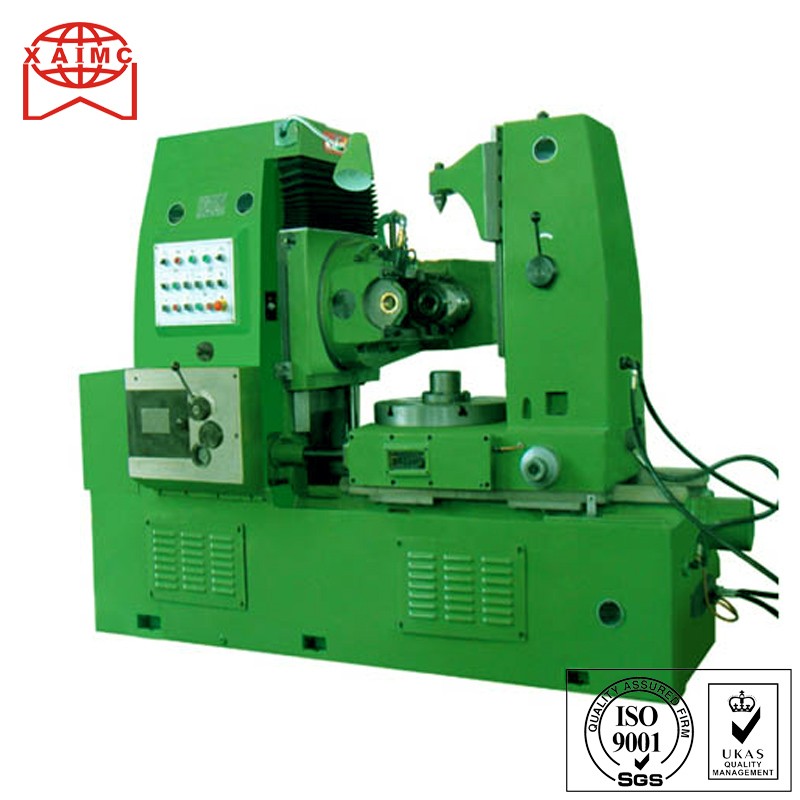

GEAR HOBBING MACHINE YB3180

The machine has rigid structure, good accuracy, easy operation and simple setup.

Either conventional or climb method can be used with machine.

The machine is equipped with an automatic shu-down divice, safetysecuing mechanisms, and an auto lubricating system.

The machine has a square woking, semi-automatic cycle function, suitable for mass production and machines management, greatly raise efficiency.

Vertical tool post can be provided according to the specific requirement of customers.

| GEAR HOBBING MACHINE YB3180 | |

| Item | Main Specification |

| Max diameter of workpiece | 550mm (with rear post) 800mm(without rear post) |

| Max module of workpiece | 10mm |

| Max machining width workpiece | 320mm |

| Min teenth of workpiece | Zmin/Kn=7 |

| Max diameter of cutters | 180mm |

| Max length of cutters | 180mm |

| Diameter of changeable mandrel of cutters | 22,27,32,40mm |

| Max rotary angle of headstock | 60 |

| Max axial motion of cutters | 60mm |

| Dia between table and axis of cutters | MAX 585MM MIN235MM |

| Dist between table and bearing end of rear post | max 600mm min 400mm |

| Dia of mandrel of workpiece | 35mm |

| Steps of spindle speed | 8steps |

| Range of spindle speed | 40-200r.p.m. |

| Range of axial feed | 0.4-4mm/table per turn |

| Machining precision | 7th grade accord to JB179-60 |

| Dimensions | 2765x1420x1850 |

Min diameter of workpiece is thedistance between axis of workpieceand axis of cuter minus min diameterof cutter.

The acessaries with the machine:

1.The machining arbor 1set

2.The hob kasbor 1set

3.The exchangeable gear 57 pieces

4.The tols for adjustment

A.The single ended spanner 5 pieces

B.The iner hexigon spanner 1 piece

C.The fork spanner 1 piece

D.The oil gum 1 piece .