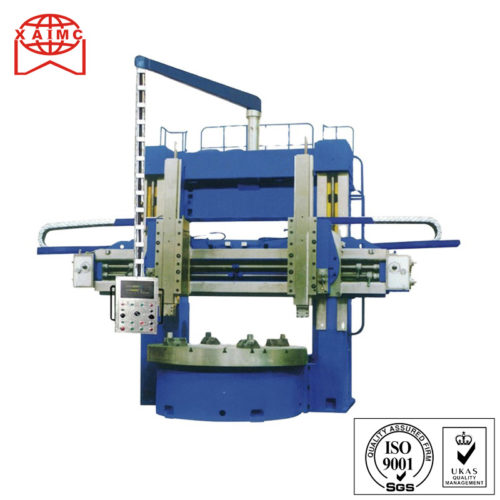

Heavy Duty Lathe CW61125D CW61140D CW61160D CW61180D CW61200D

High Spindle Speed Automatical Horizontal Lathe Machine

Product overview

This high spindle speed automatical horizontal lathe machine mainly undertakes all kinds of turning works, it can turning the face, external circular and inner hole of many kinds of workpieces as well as metric thread, inch screw thread, module thread and pitch thread, etc.

This high spindle speed automatical horizontal lathe machine is available on cutting short taper with top rest alone, and also this machine can be used on cutting long taper cooperated with longitudinal feed motor. This high spindle speed automatical horizontal lathe machine has a high power, high speed and high rigidity.

This high spindle speed automatical horizontal lathe machine can do the powerful turning with carbide cutters to processing various ferrous metals and non-ferrous metals.

|

SPECIFICATION

|

Unit

|

CW6 1/2 100D

|

CW61 1/2 25D

|

CW61 1/2 40D

|

CW61 1/2 60D

|

|

|

Capacity

|

Max.swing diameter over bed

|

mm

|

1040

|

1290

|

1440

|

1640

|

|

Max.swing diameter over carriage

|

mm

|

650

|

900

|

1030

|

1030

|

|

|

Max.swing diameter on gap

|

mm

|

1500

|

1750

|

1900

|

2100

|

|

|

Width of bed

|

mm

|

755

|

||||

|

Max.length of workpiece

|

mm

|

1000-12000

|

||||

|

Max.load

|

t

|

6

|

||||

|

Spindle

|

Spindle nose

|

|

A15

|

|||

|

Spindle bore diameter

|

mm

|

120

|

||||

|

Spindle bore taper

|

|

Metric No.140

|

||||

|

Range of spindle speed

|

rpm

|

3015-315 21kinds 3.5-290 12kinds

|

||||

|

Spindle front bearing inner diameter

|

mm

|

200

|

||||

|

Feed

|

Longitudinal feeds range

|

rpm

|

0.01-12 56kinds

|

|||

|

Transversal feeds range

|

mm/r

|

0.05-6 56kinds

|

||||

|

Metric threads range

|

mm

|

1-120 44kinds

|

||||

|

Inch threads range

|

tpi

|

3/8-28 31kinds

|

||||

|

Moudle threads range

|

mm

|

0.5-60 45kinds

|

||||

|

Pitch threads range

|

tpi

|

1-56 25kinds

|

||||

|

Tailstock

|

Taper of tailstock sleeve

|

Morse

|

Metric No.80

|

|||

|

Travel of tailstock sleeve

|

mm

|

300

|

||||

|

Diameter of tailstock sleeve

|

mm

|

160

|

||||

|

MOTORS

|

Main motor power

|

kW

|

22

|

|||

|

Rapid motor power

|

kW

|

1.5

|

||||

|

Coolant pump power

|

kW

|

0.125

|

||||

Features

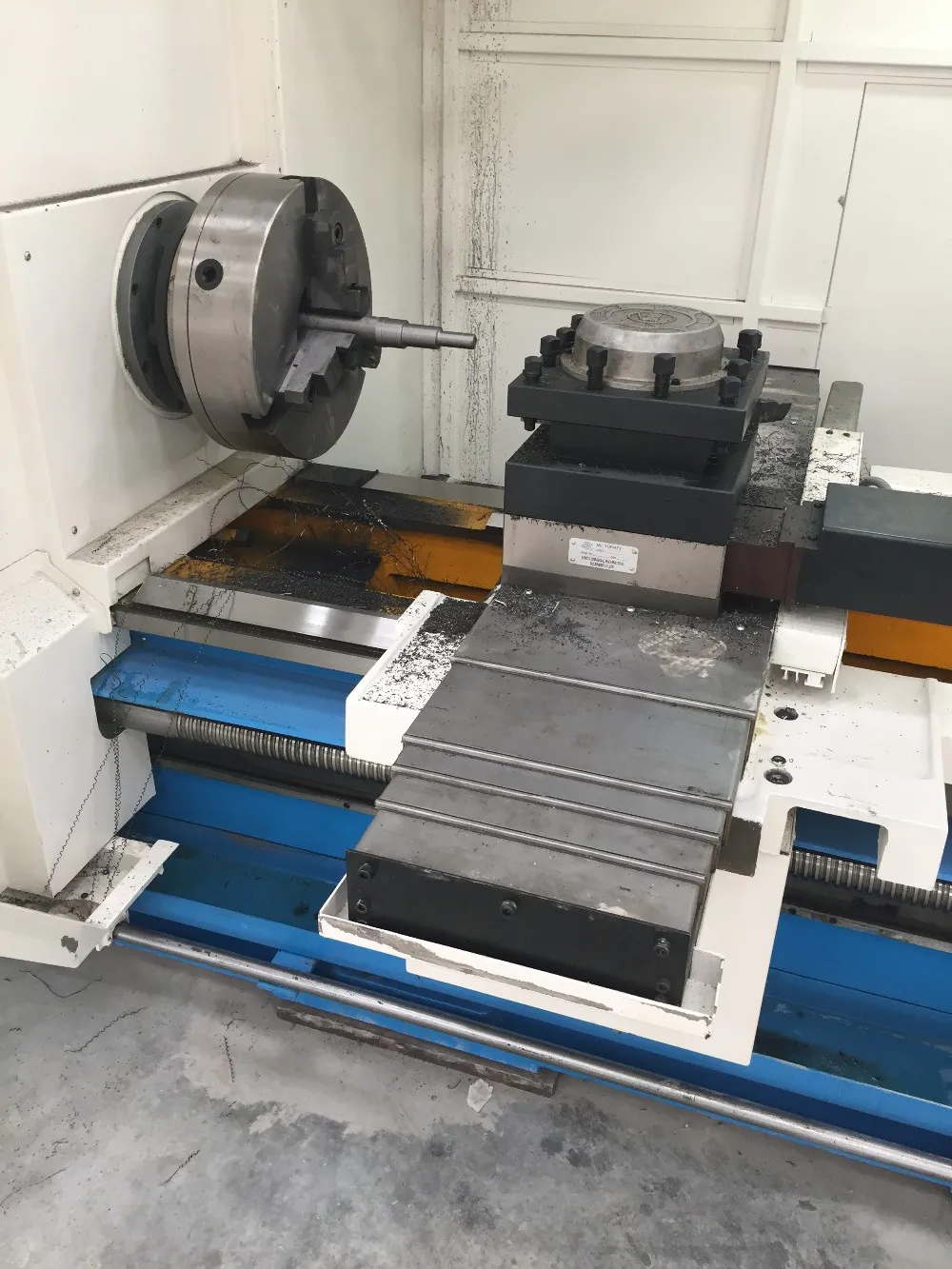

1.The lathe can perform to turn end -faces, cylindrical surfaces and internal holes of various parts as well as metric ,inch, module and pitch threads.

2.The top slides may be operated individually by power for cutting shot taper, long taper can be turned automatically through the compound movement combining longitudinal feed with the top slide feed, moreover, the machines may be used for drilling, boring and trepanning .

3.They are characteristic of power, high spindle speed, high rigidity.

4.The various ferrous and won-ferrous metals parts may be turned through the heavy cutting by carbon alloy tools.

5.This machine is suitable for the work of half-finishing processing and finishing processing, when the workpieces are heavy or eccentric, please pay an attention to the chuck speed limit and workpiece balance.

6.Guideway has quenching and grinding treatment. Hardness could be HRC52.

Chuck

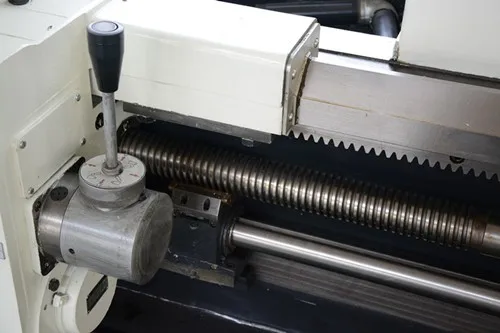

screw mandrel

handwheel

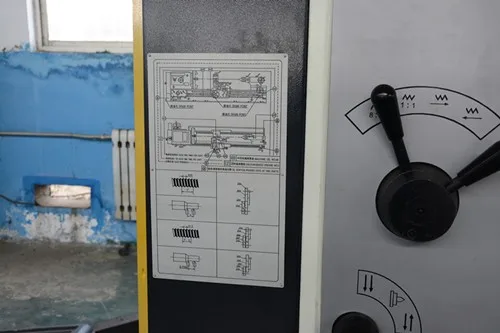

panel

|

Packaging |

|

|

Size

|

According to high spindle speed automatical horizontal lathe machine size bought by client. |

|

Weight

|

According to high spindle speed automatical horizontal lathe machine bought by client. |

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Inspection work including checking the factory strength, processing site, assebly site, finished production site and so on.then we talk with customers about detailed request for machines, and if need, we could take our freinds to our customr’s site for checking, knowing more about the machines.

Q:Are you manufacturer?

A: Yes, we are manufacturers of horizontal lathe equipments, we have our own technical team, and about 80,000 sq.m workshop, welcome to visit us!

Q:What payment terms do you accept?

A: We are flexible on payment terms,we can aslo help you on financing,please contact us for details!

Q:What information will you need to make the proposal?

A: The max swing over bed, max weight of workpiece, and your special requirements.

Q:What should I do to start a new business?

A: Please contact us immediately,we provide free pre-sales consultant service. Also we can help you to solve the worker training.

Q: Do you provide training and maintenance?

A: Yes. In order to your more efficiency for production, when the horizontal lathe has arrived at the importer’ s port.

Our company will send engineers to installing the horizontal lathe machine and responsible for training the worker of customer until they can operating the machine skillful.

During the warranty time, if the device can ‘t work normally, after receiving your notice, within 24 hours, we will send

engineers to your factory for processing; If it is artificial damage,then need to charge a cost.

Each horizontal lathe leaving the factory will be along with related English instructions including maintenance manual and operation manual.

Q:Why choose you?What is the difference between you and other Chinese supplier?

A: We have specialized in this area for over 20 years.Our horizontal lathe machines are exported to Russia,India,UAE,

South Korea,Canada,Vietnam,Thailand,Mexico,Turkey and etc.

You can get higher quality product & better professional service from Hitech with same price.