and other systems and various connecting pipelines. The pipelines of the hydraulic system are all connected by high-pressure flanges to avoid leakage of hydraulic oil. All oil pipes are pickled before welding, and then after welding slag, deburring and secondary pickling to ensure the cleanliness of the hydraulic pipeline.

|

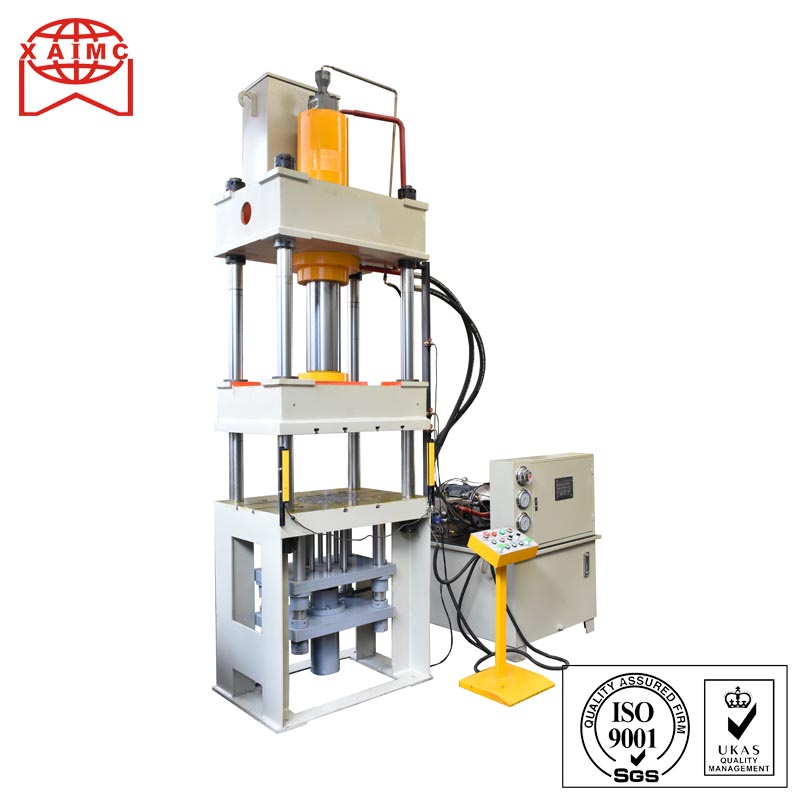

Four-column hydraulic press

|

|

Optional:

|

|

#Optoelectronic protective device

|

|

#Moving table

|

|

#Floating guide-way and rolling bracket for die exchange

|

|

#Blanking buffer device

|

|

#Quick die clamping mechanism

|

|

#Industrial touching screen monitor

|

|

#Stroke,pressure,speed digital control device

|

|

#Water cooler device Displacement sensor

|

|

#Blank holder slide,hydraulic cushion corners respectively regulating device(stretching asymmetric parts)

|

|

Type

|

Unit

|

63T

|

100T

|

160T

|

200T

|

315T

|

630T

|

1000T

|

2000T

|

|

Nominal Pressure

|

KN

|

630

|

1000

|

160

|

2000

|

3150

|

6300

|

10000

|

20000

|

|

Ejecting Force

|

KN

|

100

|

200

|

250

|

400

|

630

|

1000

|

1000

|

2000

|

|

Max.working pressure

|

Mpa

|

25

|

26.2

|

26

|

25

|

25

|

26

|

26

|

27

|

|

Slide stroke

|

mm

|

500

|

500

|

500

|

700

|

800

|

900

|

900

|

1400

|

|

Max.opening height

|

mm

|

700

|

900

|

900

|

1120

|

1250

|

1500

|

1500

|

1600

|

|

Table Size(F.B.)

|

mm

|

500

|

580

|

800

|

900

|

1200

|

1500

|

1600

|

2000

|

|

Table Size(L.R.)

|

mm

|

500

|

710

|

800

|

900

|

1200

|

1500

|

1600

|

2800

|

|

Ejecting stroke

|

mm

|

160

|

200

|

200

|

250

|

300

|

400

|

400

|

450

|

|

Idle stroke

|

mm/s

|

76

|

100

|

100

|

100

|

>100

|

>100

|

>100

|

>100

|

|

Pressing

|

mm/s

|

10

|

8-15

|

8-15

|

8-15

|

8-15

|

10

|

12

|

10

|

|

Return

|

mm/s

|

60

|

60

|

60

|

70

|

70

|

65

|

80

|

>75

|

|

Power of motor

|

KW

|

5.5

|

7.5

|

15

|

18.5

|

22

|

45

|

68

|

134

|

|

Total Weight

|

T

|

2.5

|

4

|

7

|

12

|

15

|

30

|

48

|

145

|