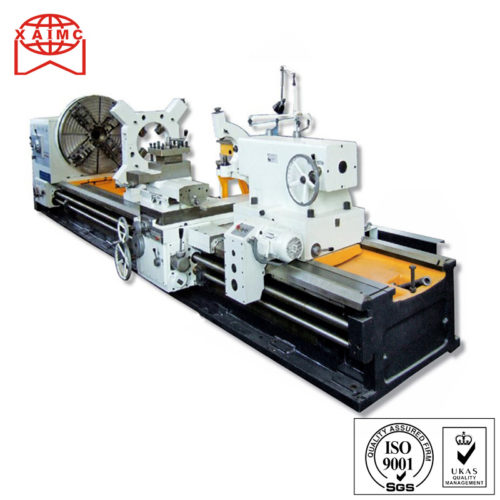

Manual Vertical Turret Lathe C5225

-

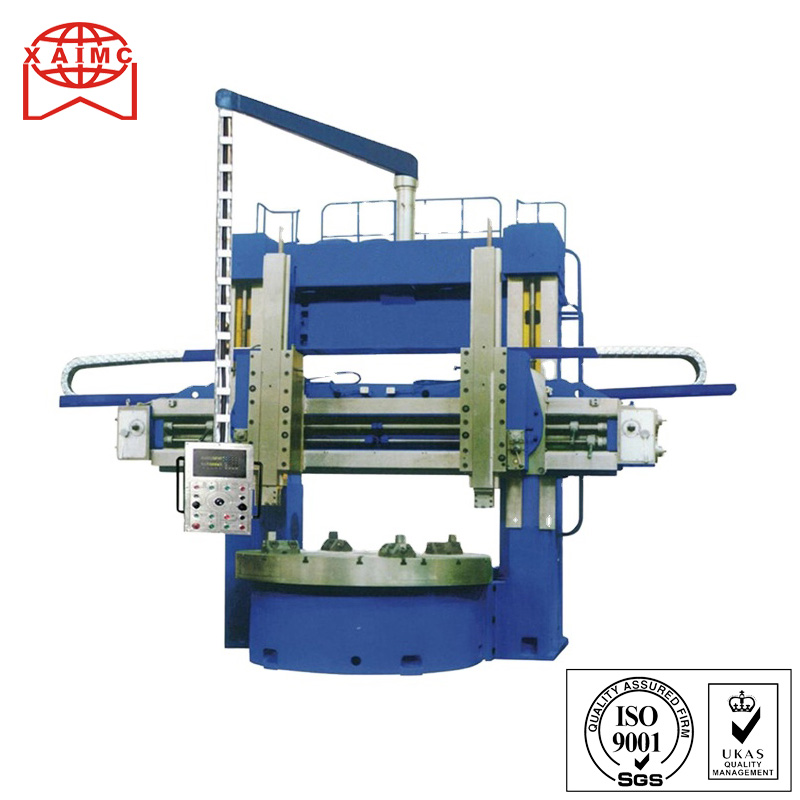

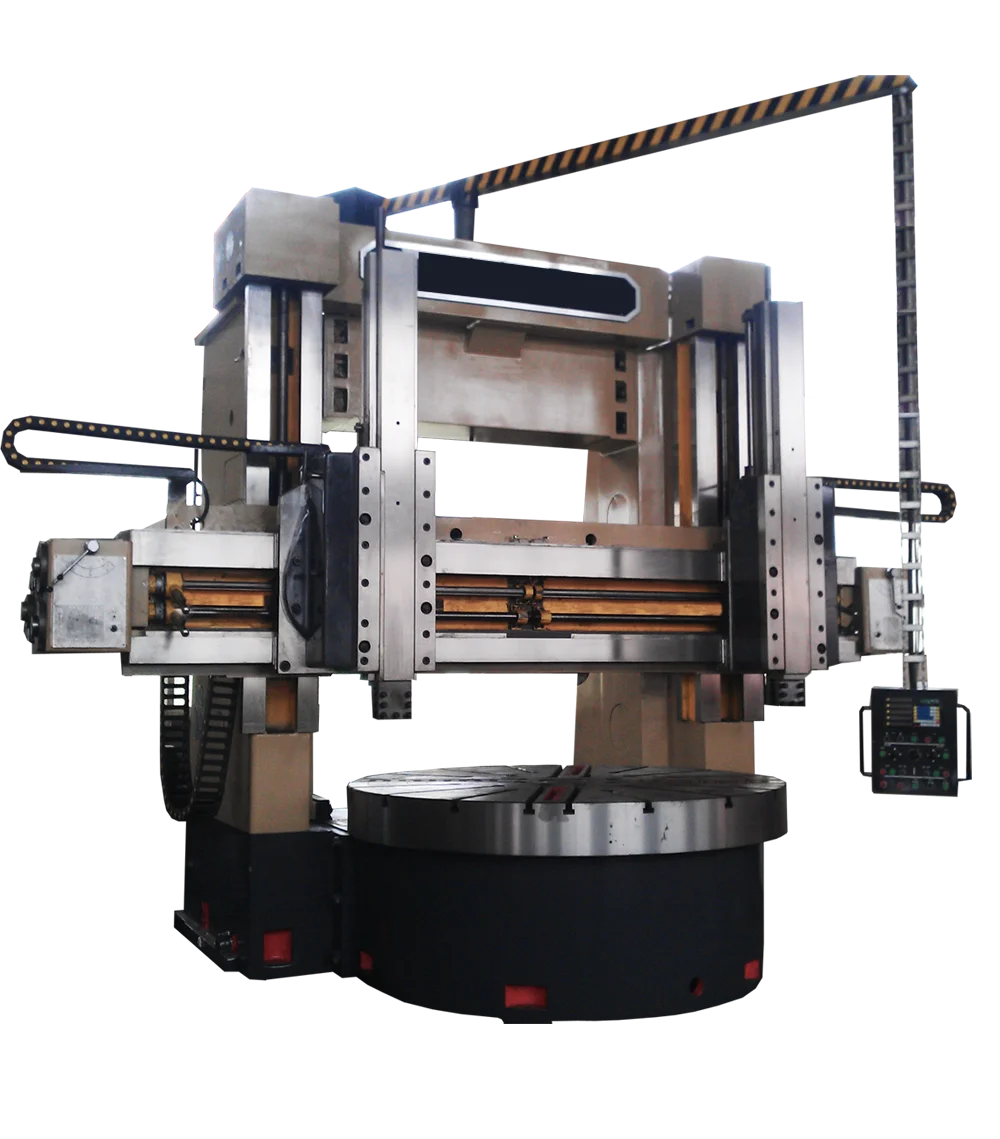

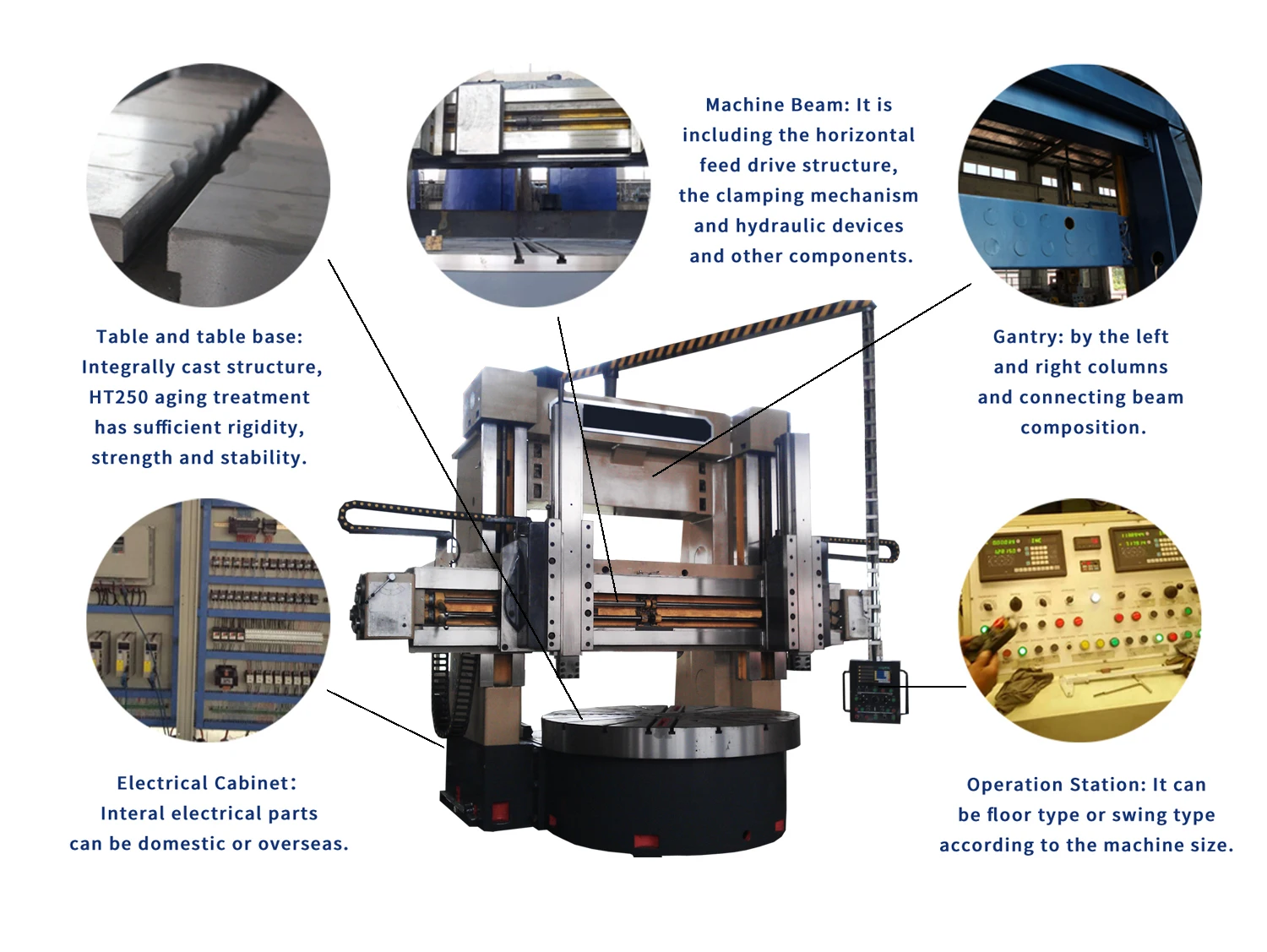

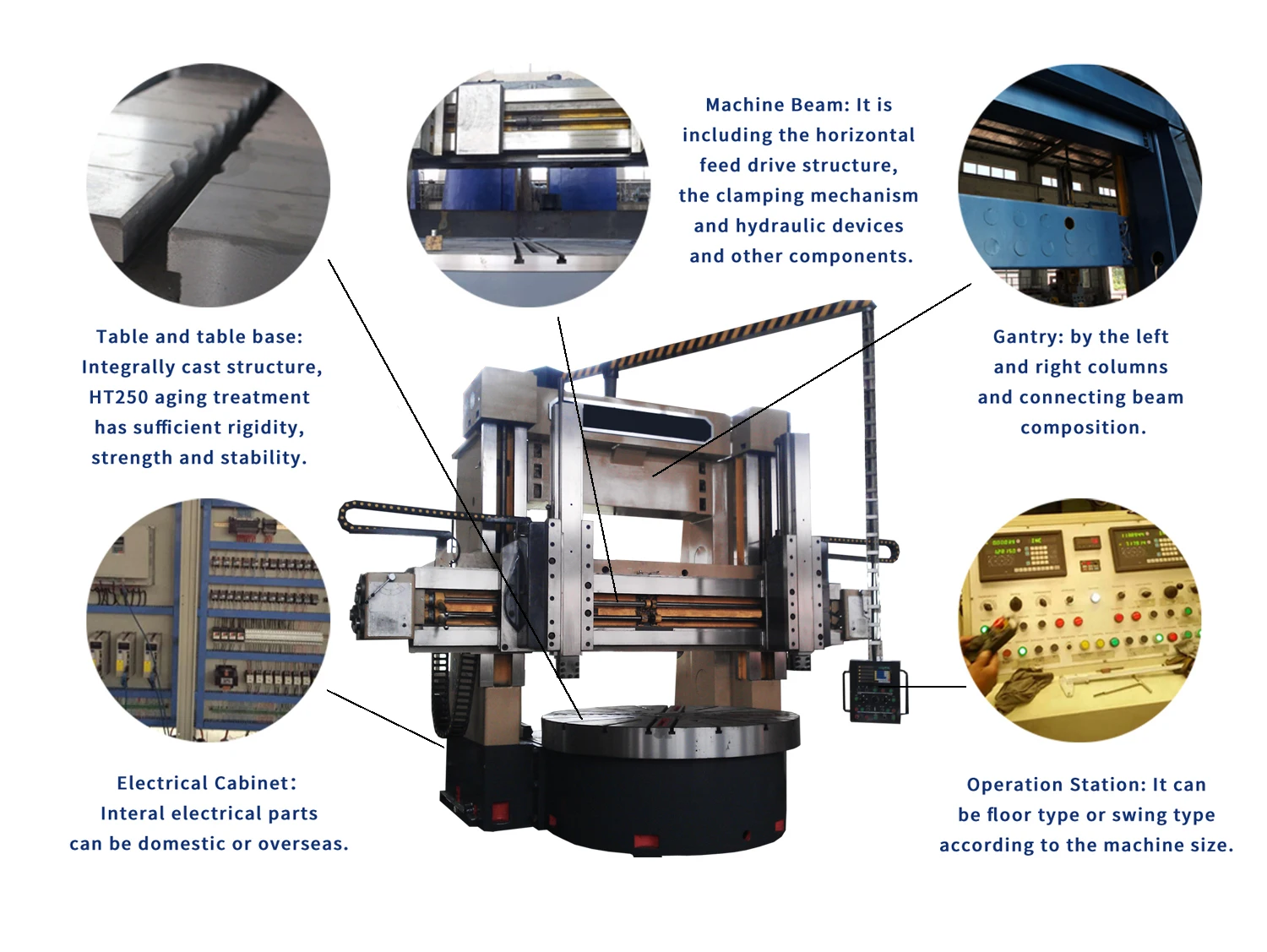

Double Column Vertical Lathe MachineNameUnitC5225C5240C5250C5263C5280Max cutting diameter of workpiecemm25004000500063008000Workbench diametermm22503200450057006300/7200Max height of workpiecemm1600/20002000/2500/31502000/2500/31502500/3150/40003500/4000/5500Max weight of workpiecet10/1520/3232/5080/12560/80/150Workbench speed ranger/min2~632-500.5~400.5~400.32~32Max torque of worktablekn.m6380100150200Tool Rest Section sizemm40×5040×5050×5060×6060×60Main motor powerkw55557590132machine weightt3540/50/6060/100100/180210/240/260Single column vertical lathe machineITEMSUNITC5112C5116C5120C5123C5126Max. turning diametermm12501600200023002600Max. height of workpiecemm10001200125013501350Max. weight of workpiecetons3.25888Worktable diametermm10001400180020002300Worktable speed seriesstep1616161616Worktable speed ranger/min6.3-2005-1604-1253.2-1002.5-80Main motor powerKW2230303037Beam travelstep65090090010001000Machine weighttons8.512.517.518.519.5

Double Column Vertical Lathe MachineNameUnitC5225C5240C5250C5263C5280Max cutting diameter of workpiecemm25004000500063008000Workbench diametermm22503200450057006300/7200Max height of workpiecemm1600/20002000/2500/31502000/2500/31502500/3150/40003500/4000/5500Max weight of workpiecet10/1520/3232/5080/12560/80/150Workbench speed ranger/min2~632-500.5~400.5~400.32~32Max torque of worktablekn.m6380100150200Tool Rest Section sizemm40×5040×5050×5060×6060×60Main motor powerkw55557590132machine weightt3540/50/6060/100100/180210/240/260Single column vertical lathe machineITEMSUNITC5112C5116C5120C5123C5126Max. turning diametermm12501600200023002600Max. height of workpiecemm10001200125013501350Max. weight of workpiecetons3.25888Worktable diametermm10001400180020002300Worktable speed seriesstep1616161616Worktable speed ranger/min6.3-2005-1604-1253.2-1002.5-80Main motor powerKW2230303037Beam travelstep65090090010001000Machine weighttons8.512.517.518.519.5 Detailed Images

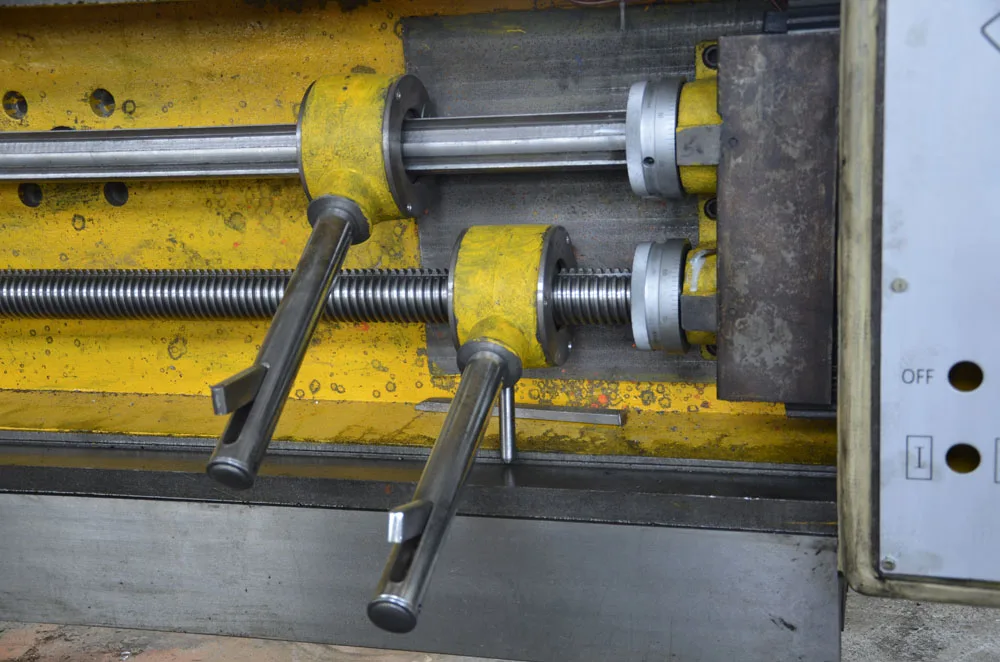

Detailed Images CastingThe casting is made of HT250-300 material, and there is no residual resin sand on the surface of the casting after smother,

CastingThe casting is made of HT250-300 material, and there is no residual resin sand on the surface of the casting after smother,

tempering and aging treatment, which shows that we strictly adhere to each core process and ensure the strength, rigidity,

precision, stability and durability of the machine tool.Smouldering fire:After casting, we will place the workpiece in the furnace and keep it at a high temperature for a long period of time and then it

will naturally drop to room temperature as the furnace heats up and then go to the next process.Tempering :

After rough machining, the castings need to be further relieved by tempering in a high temperature furnace, which will cost most

of the cost and time for machine tools

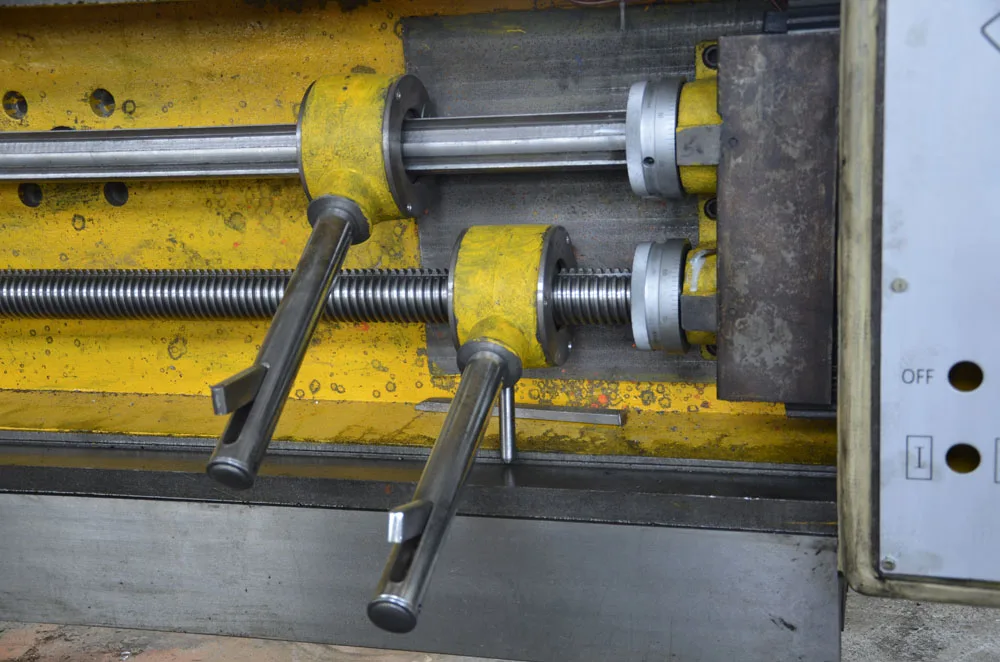

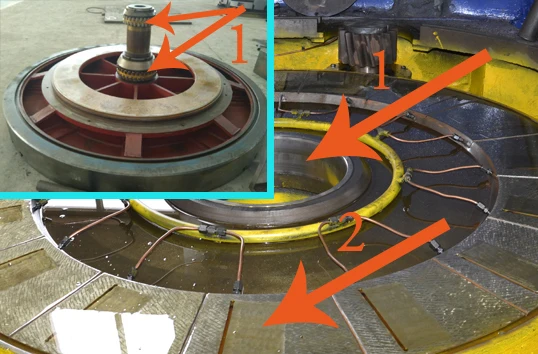

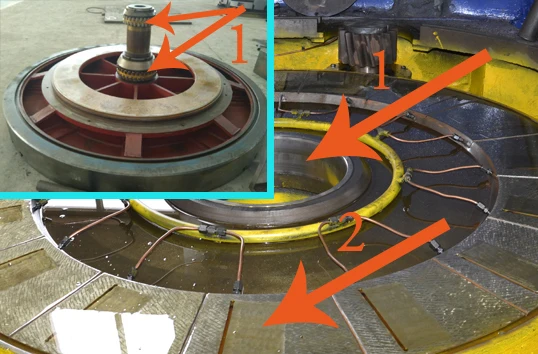

1.Heavy-duty clearance bearing:1)Combined with hydrostatic guide, the radial and axial accuracy is guaranteed.

1.Heavy-duty clearance bearing:1)Combined with hydrostatic guide, the radial and axial accuracy is guaranteed.

2)Double – combination clearance bearing

3)The clearance can be adjusted at any time when the radial and axial accuracy of the table is out of tolerance

4)Bearing with ZWZ or NSK2.Hydrostatic guideway

1)Carrying large

2)Strong rigidity

3)Low friction coefficient

4)Rotate smoothly4 jaw chuck -Manual1)4 – jaw loaded plus force chuck

2)Overload clamping

3) Large controllable range

4)3 jaw hydraulic chuck is optional below 1600mm

5)The rotary encoder is installed in the working table, which can realize the function of turning different size threads

6)The complex workpiece can be machined with numerical control system

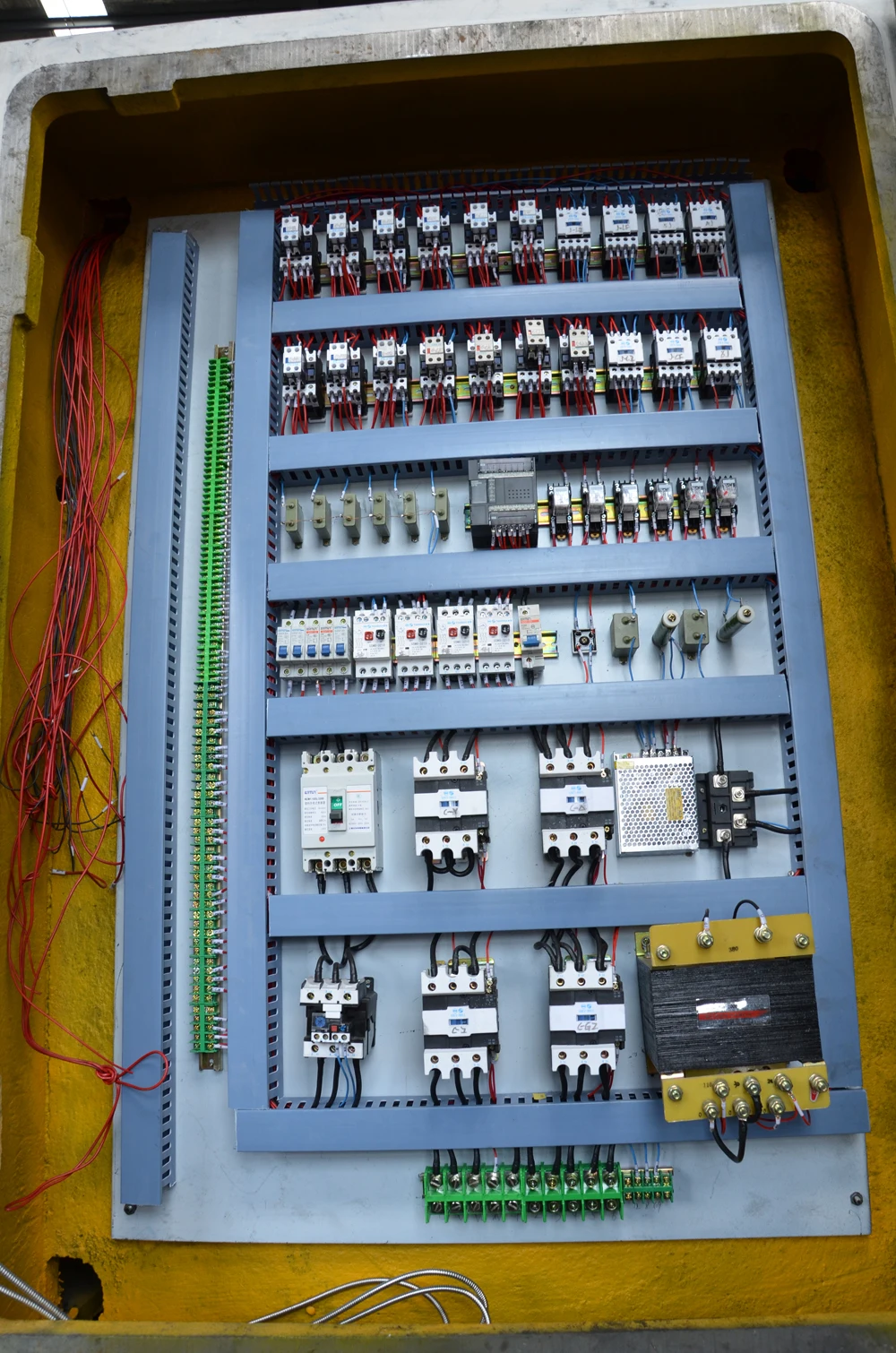

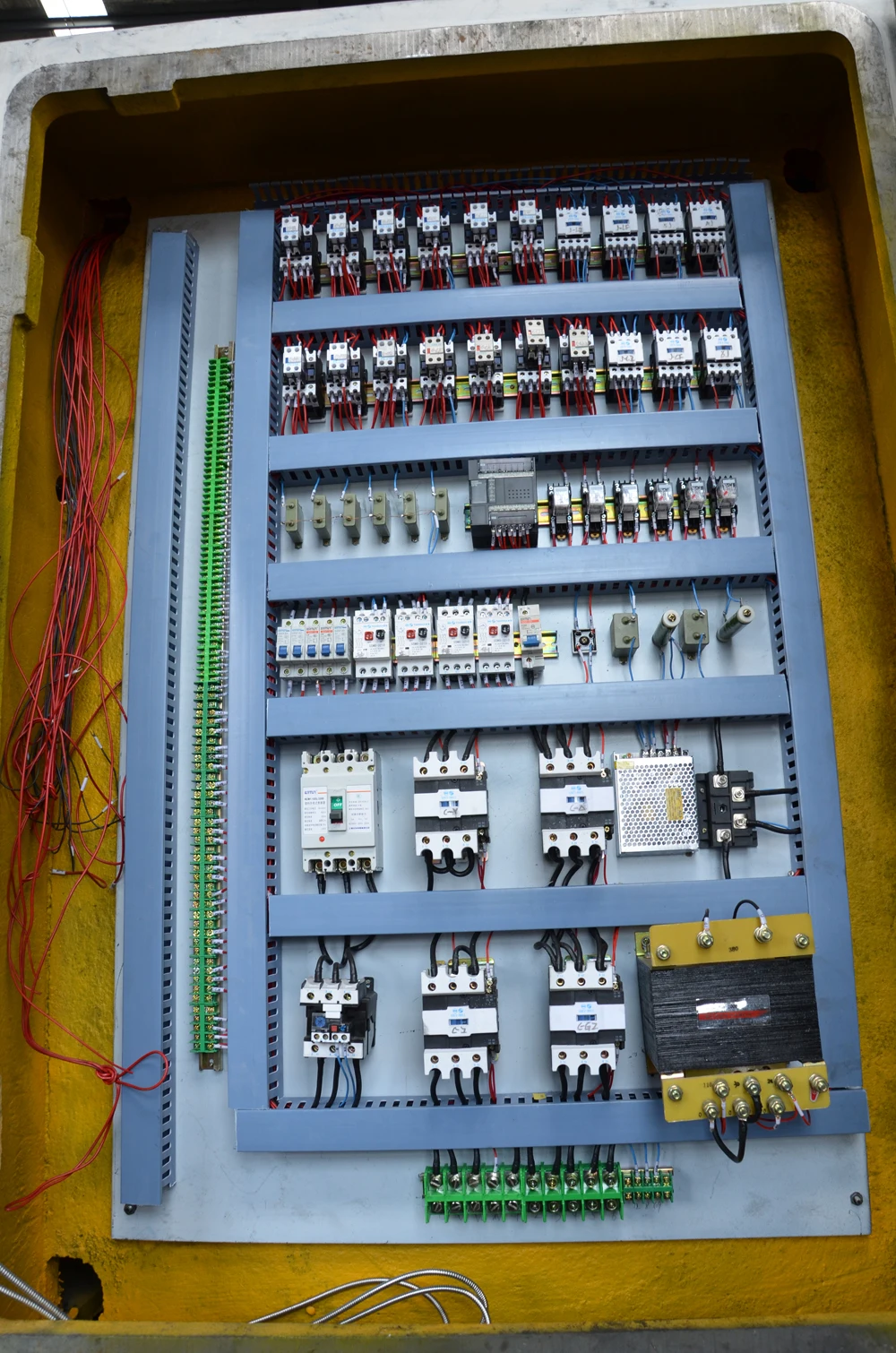

Electrical SystemMachine adopts electric control elements are installed in the power distribution cabinet, all operating elements focused on the

Electrical SystemMachine adopts electric control elements are installed in the power distribution cabinet, all operating elements focused on the

hanging button site installation.Hydraulic stations:It includes a table static pressure system, a main drive system, a beam clamping system, and a vertical turret tamping hydraulic balance system. The hydraulic device has a pressure protection function, and it will close automatically if the pressure is not used properly.

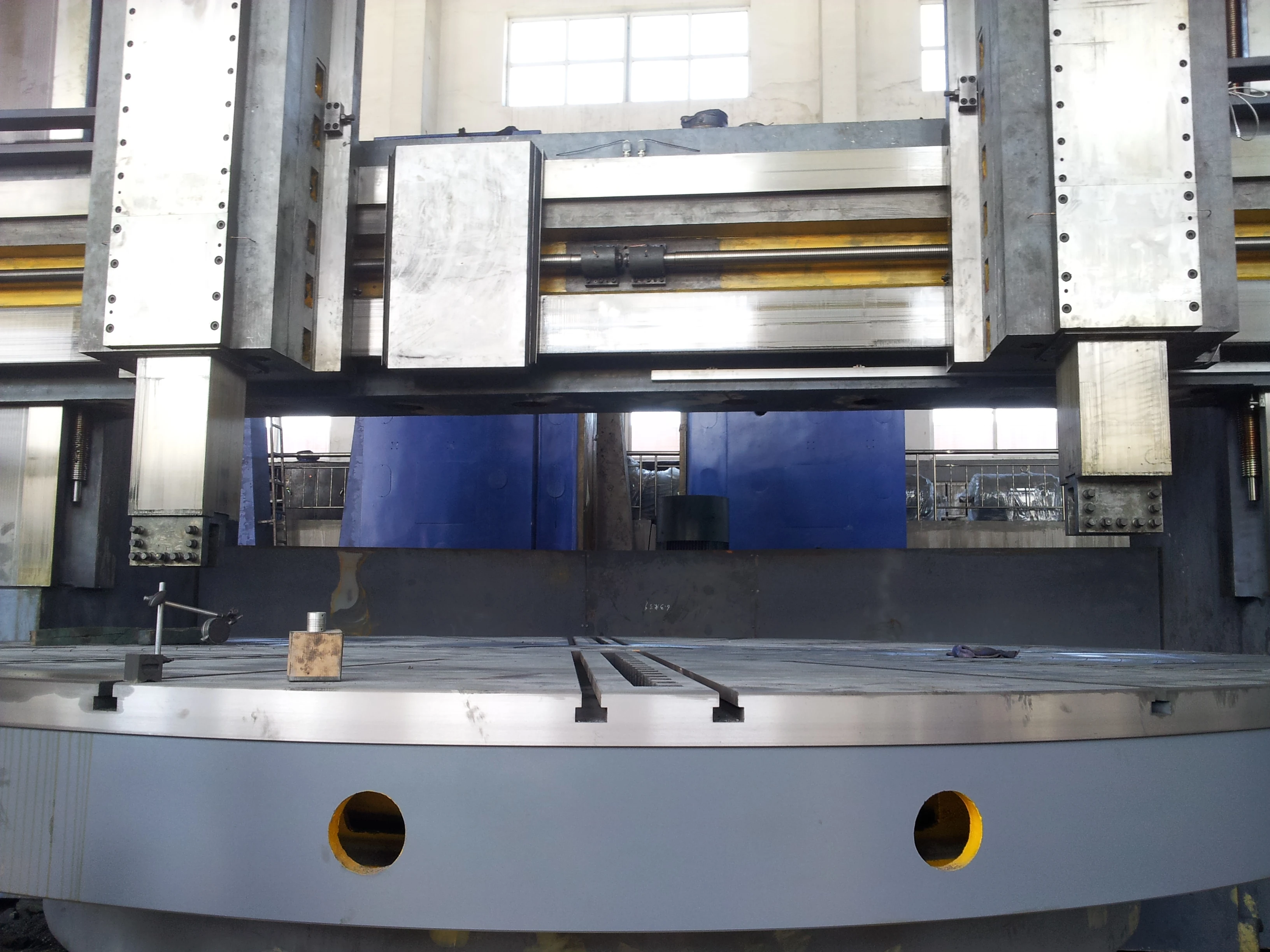

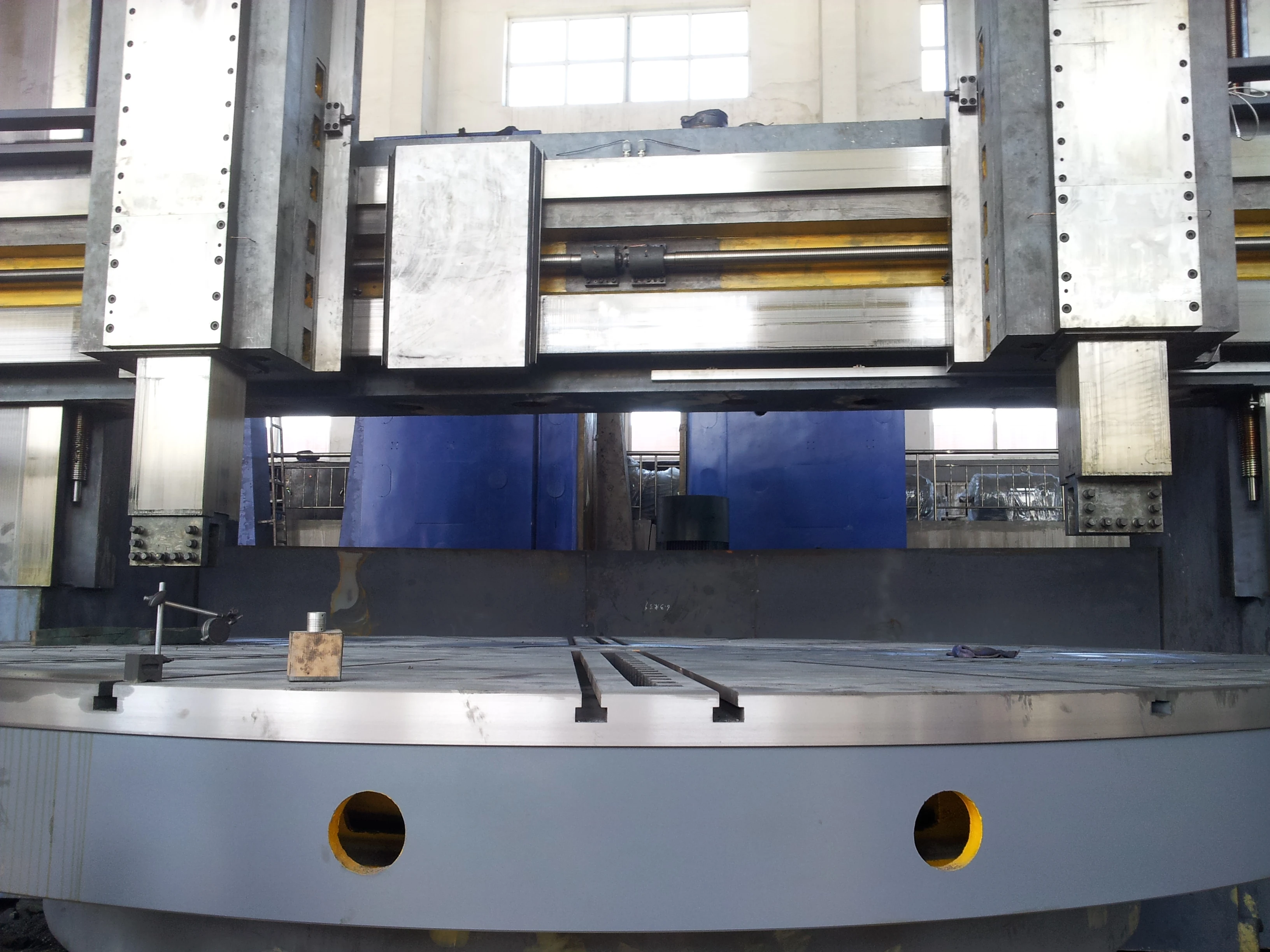

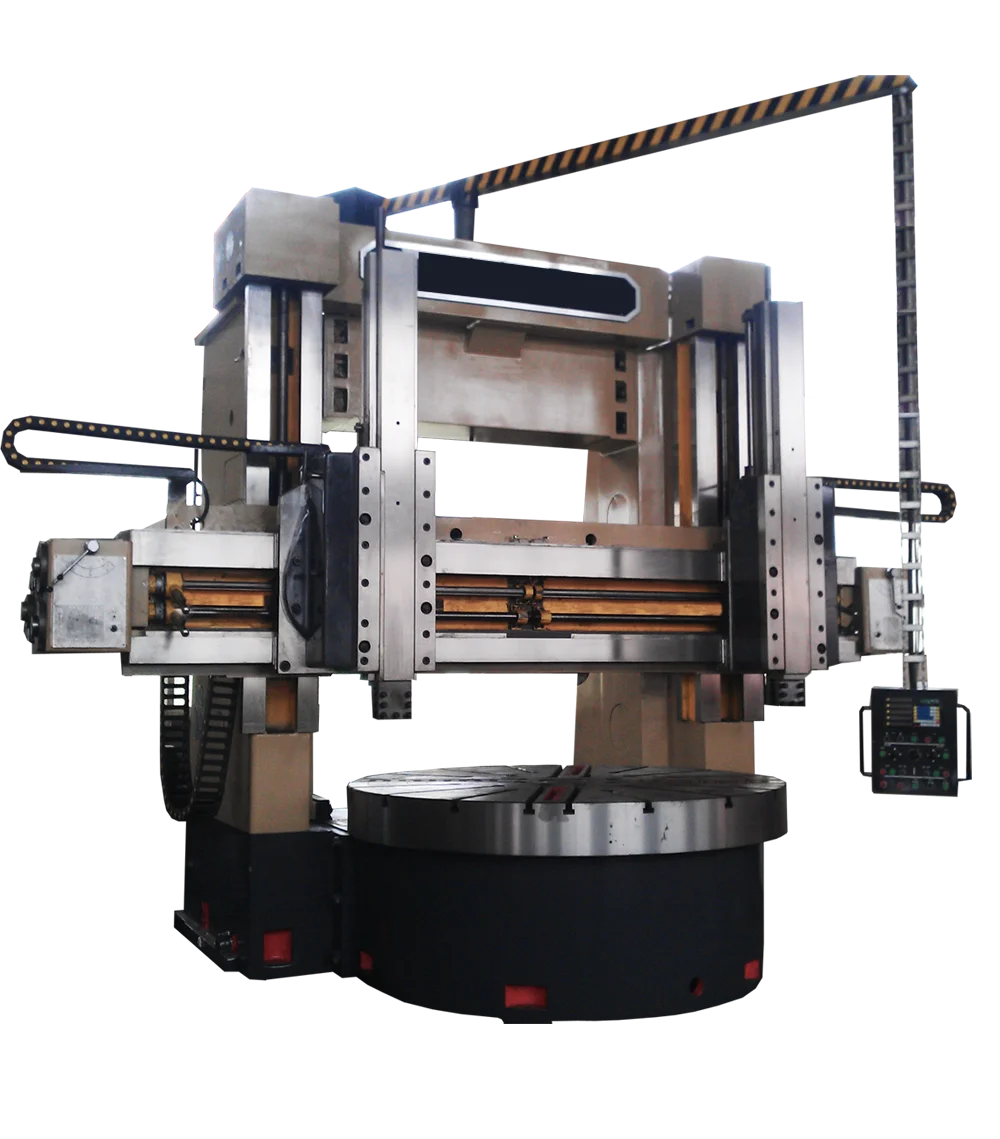

GANTRYGantry is consisting of the left and right columns and connecting beams. In the upper part of the gantry there are left and right

GANTRYGantry is consisting of the left and right columns and connecting beams. In the upper part of the gantry there are left and right

lifting boxes, driven by the AC motor, through the worm gear and double screw to make the beam along the left and right column

rails to move up and down. Machine tools left and right columns, beams and other large-scale use of high strength, low stress cast

iron material, hardness HB170-190, the machine has greater strength and higher stiffness, after aging treatment to eliminate

stress and ensure the accuracy of the machine.Machine detail