Main technical data:

| Specification | Shearing Thickness | Shearing Width | Strokes | Backgauge Rang | Shearing Angler | Main power |

| mm | mm | mm-¹ | mm | ( 。) | kw | |

| QC11K-6×2500 | 6 | 2500 | 10 | 15-600 | 0.5~2.5° | 7.5 |

| QC11K-6×3200 | 6 | 3200 | 8 | 15-600 | 0.5~2.5° | 7.5 |

| QC11K-6×4000 | 6 | 4000 | 7 | 15-600 | 0.5~2.5° | 7.5 |

| QC11K-6×5000 | 6 | 5000 | 8 | 15-800 | 0.5~2° | 15 |

| QC11K-6×6000 | 6 | 6000 | 6 | 15-800 | 0.5~2° | 15 |

| QC11K-8×2500 | 8 | 2500 | 10 | 15-600 | 0.5~2.5° | 11 |

| QC11K-8×3200 | 8 | 3200 | 8 | 15-600 | 0.5~2.5° | 11 |

| QC11K-8×4000 | 8 | 4000 | 7 | 15-600 | 0.5~2.5° | 11 |

| QC11K-8×5000 | 8 | 5000 | 8 | 15-800 | 0.5~2° | 15 |

| QC11K-8×6000 | 8 | 6000 | 6 | 15-800 | 0.5~2.5° | 22 |

| QC11K-12×2500 | 12 | 2500 | 9 | 20-800 | 0.5~2.5° | 18.5 |

| QC11K-12×3200 | 12 | 3200 | 7 | 20-800 | 0.5~2.5° | 18.5 |

| QC11K-12×4000 | 12 | 4000 | 6 | 20-800 | 0.5~2.5° | 18.5 |

| QC11K-12×5000 | 12 | 5000 | 5 | 20-800 | 0.5~2.5° | 18.5 |

| QC11K-12×6000 | 12 | 6000 | 4 | 20-800 | 0.5~2.5° | 30 |

| QC11K-16×2500 | 16 | 2500 | 8 | 20-800 | 0.5~3° | 22 |

| QC11K-16×3200 | 16 | 3200 | 7 | 20-800 | 0.5~3° | 30 |

| QC11K-16×4000 | 16 | 4000 | 6 | 20-800 | 0.5~3° | 30 |

| QC11K-16×5000 | 16 | 5000 | 6 | 20-800 | 0.5~2.5° | 30 |

| QC11K-16×6000 | 16 | 6000 | 5 | 20-800 | 0.5~2.5° | 37 |

| QC11K-20×2500 | 20 | 2500 | 6 | 20-1000 | 0.5~3° | 30 |

| QC11K-20×3200 | 20 | 3200 | 5 | 20-1000 | 0.5~3° | 30 |

| QC11K-20×4000 | 20 | 4000 | 6 | 20-1000 | 0.5~3° | 30 |

| QC11K-20×5000 | 20 | 5000 | 5 | 20-1000 | 0.5~2.5° | 37 |

| QC11K-20×6000 | 20 | 6000 | 5 | 20-1000 | 0.5~2.5° | 45 |

| QC11K-25×2500 | 25 | 2500 | 5 | 20-1000 | 0.5~3.5° | 37 |

| QC11K-25×3200 | 25 | 3200 | 4 | 20-1000 | 0.5~3.5° | 37 |

| QC11K-25×4000 | 25 | 4000 | 3 | 20-1000 | 0.5~3.5° | 37 |

| QC11K-32×2500 | 32 | 2500 | 4 | 20-1000 | 0.5~3.5° | 55 |

| QC11K-32×3200 | 32 | 3200 | 3 | 20-1000 | 0.5~3.5° | 55 |

| QC11K-40×2500 | 40 | 2500 | 3 | 20-1000 | 0.5~4° | 75 |

| QC11K-40×3200 | 40 | 3200 | 3 | 20-1000 | 0.5~4° | 75 |

Description and specifications given in this catalogue are subject to modification without notice.

QCl2K cutting machine parts CNC system

|

E21S

|

A high-resolution LCD display and English & Chinese display, one page programming.

Rear stopper: intelligent positioning or choose to manually, remove the mechanical hand positioning device. Cutting stroke: built-in shear time relay, simple easy to use, cost savings for the company. Shear angle: built-in shear angle adjustable function. Blade gap: encoder feedback, show the blade gap timely, simple easy to use. One key backup and recovery, recovery parameters at any time. All buttons on the panel are sensitive switch, have passed EMC, High-Low temperature, vibration, etc. strict testing to ensure the stability and service life. It has been certified by CE, meet the demand of overseas market. |

|

E200-S

|

Hd 275 * pixel LCD display

After the control of material should block The blade gap should control The shear trip, Should control After the actual position should block material with programming value shows at the same time Shear should count 100 program should step Face plate installation should Should the servo control/variable frequency speed regulation control/double speed ac motor control

|

|

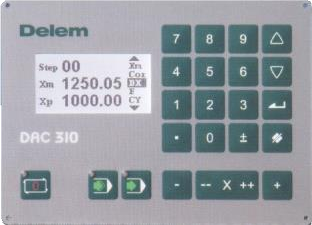

DAC310

|

Panel installation should

Should high brightness LCD display screen After should block material control Concession control should Shearing Angle control should The shear clearance should control Should travel control shear Should the axis can be manual movement Pressure control should |